- Joined

- Oct 4, 2011

- Messages

- 727

Here is a pic of DEXTER on his first lathe! (Locked OUT of Coarse)!

Another few years and you need to get him his first tool box and safety glasses. Let him have a small space in the shop for his stuff.

Jeff

Here is a pic of DEXTER on his first lathe! (Locked OUT of Coarse)!

:roflmao:

:roflmao:

Another few years and you need to get him his first tool box and safety glasses. Let him have a small space in the shop for his stuff.

Jeff

Several projects got done today.

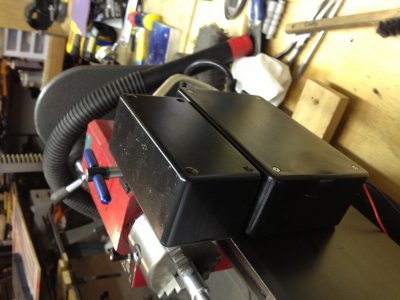

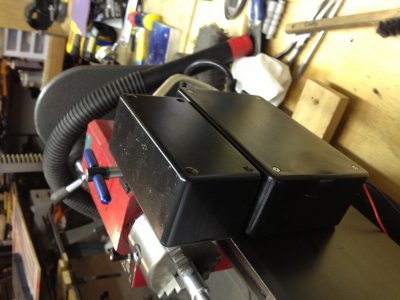

Motor control for the leadscrew for my minilathe. Used an Arduino that I had laying around to do the PWM, overkill, but eventually I'm thinking of adding a smoother control for the spindle, and interlock functions. So its already on-board and ready.

View attachment 58520

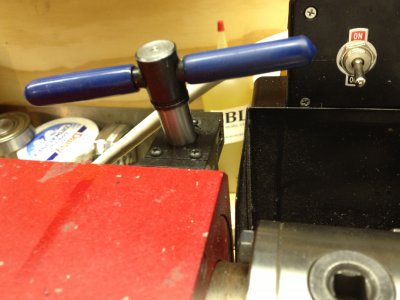

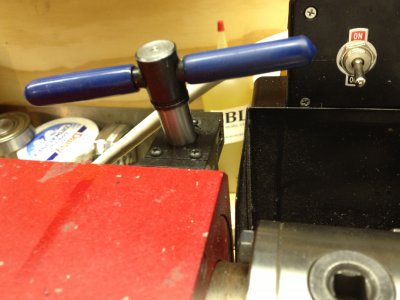

Master power for the leadscrew is tied to main power for lathe. Left switch is power for Arduino and motor, center is direction, speed knob on the right.

View attachment 58519

Radio Shack boxes house the 24vdc power supply, Arduino, and a circuit board I built to hold the transistor and 5vdc regulator for the Arduino.

View attachment 58521

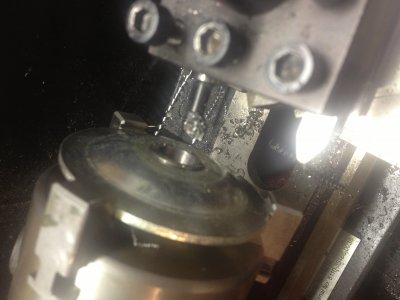

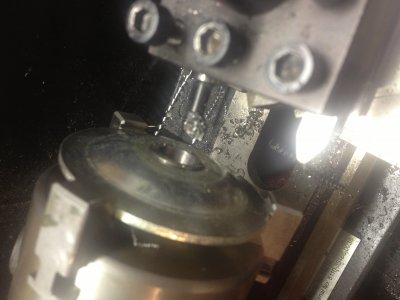

Found a nifty place to store the chuck key for the Mini. It used to house the small interlock switch for the chuck guard.

View attachment 58522

Bored and sleeved the mounting plate on my new, but in need of "repair", HF bench grinder. It was running out about 20 thou, bored it out about 100 over, pressed in a bushing, and drilled and bored for a nice tight fit. Good as "new".

View attachment 58518 :roflmao:

-Cody

Wow Cody! I am looking to make a control like this for my Sherline for a while now! I even have the Arduino etc, (newbie starter kit) and have to get started learning it all.

Mind if I pick your brain when I get there?

Bernie

I started and almost completed the tilt table that was shown on the oxtoolco video for the clausing drill press...Will attempt to take pics tomorrow!