- Joined

- Dec 8, 2013

- Messages

- 2,651

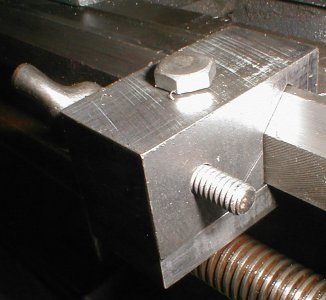

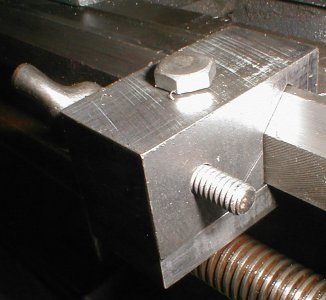

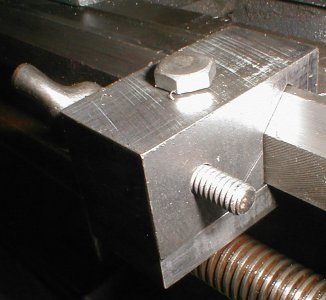

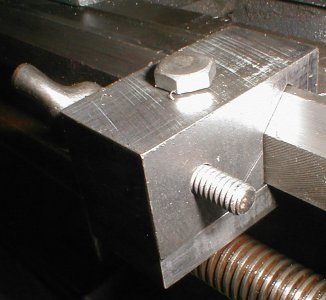

Made this carriage stop for my Logan:

The thumbscrew will have to be replaced by a proper knurled knob and the clamping bolt with a square-headed one to match the wrenches that came with the lathe. I'll also want to secure a bit of hardened steel to the carriage to keep the casting from getting beaten up.

Someday it might evolve into a micrometer stop.

The thumbscrew will have to be replaced by a proper knurled knob and the clamping bolt with a square-headed one to match the wrenches that came with the lathe. I'll also want to secure a bit of hardened steel to the carriage to keep the casting from getting beaten up.

Someday it might evolve into a micrometer stop.