-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2014 POTD Thread Archive

- Thread starter Smudgemo

- Start date

New coffee table for the house, fairly simple build. Only machining required a male 7/16-20 to 3/8-16 adaptor to bolt the pistons to the block.

Wow... That is awesome. Love it. I have seen them with pistons as feet, as well... Have you thought of doing that?

Architard, that looks much better than the stock cattywompus HF setup. Just be careful with the stock cast plates. I hear they can shatter.

Today I tried my hand at the captive nut machinist's puzzle...

Ginger was unimpressed. :-/

- Joined

- Feb 17, 2013

- Messages

- 4,407

Even though you'd gone to the trouble to form dog-bone ends???? What an ingrate!!!

PS - You don't yet have an avatar photo. This might be a nice one for you!

I made this last week. It is my Easter Egg project ;-)

The egg was made on a Tormach PCNC1100's fourth axis. What came out still had plenty of mill marks, so I placed on the lathe and filed down to a decent finish. Then used sand paper to remove the last marks, before heading to the buffing wheel for polishing. It can still be polished further, but I am not trying to do a LASER mirror here, so this is good enough for me.

It took three darned hours to carve on the fourth axis! I bet a CNC lathe would have done this in minutes. Good excuse to get me a CNC lathe...

The egg was made on a Tormach PCNC1100's fourth axis. What came out still had plenty of mill marks, so I placed on the lathe and filed down to a decent finish. Then used sand paper to remove the last marks, before heading to the buffing wheel for polishing. It can still be polished further, but I am not trying to do a LASER mirror here, so this is good enough for me.

It took three darned hours to carve on the fourth axis! I bet a CNC lathe would have done this in minutes. Good excuse to get me a CNC lathe...

- Joined

- Jan 11, 2013

- Messages

- 1,821

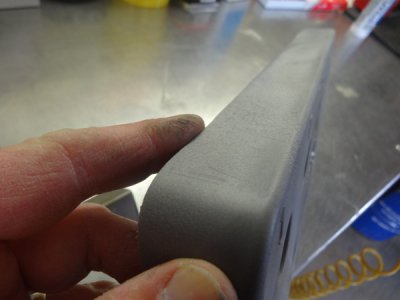

I recently picked up the 20 ton air over hydraulic bottle jack to replace the original one on my Harbor Freight 20 shop press. Anyone that has one of these presses knows that the "jack plate" that the jack sits on and has the ram welded to it is **** poor at actually keeping the ram straight. I also have the older orange version that's fully welded together and is pretty out of square. I believe the newer gray ones are bolted together and have several other improvements.

First I had to grind off some welds since the ram was actually welded to the jack plate out of plumb. I heated it up with a torch and wacked it into square. Then I removed the "guides" from the end and made new ones with some mounting holes. I spaced them further out so I could sandwich pieces of UHMW plastic between them and the uprights. I also welded on some small pieces of angle to keep the jack base from sliding around. In the original design the jack just sits on the jack plate. Now it glides up and down on the supports very tightly, no wiggle and perfectly plumb.

I've also added the T-handle to the front of the jack release valve for quick operation. I also turned a collar for the ram so that I can eventually swap different size press punches and accessories.

I need to get some more material for the next round of improvements.

These are great mods.... I think you should start a thread with this as well as posting it here. I have one of these 20 ton shop presses too... And these all address my issues! Then we could all add to it in one place... What do you think?

Bernie

Last edited by a moderator:

- Joined

- Mar 12, 2014

- Messages

- 1,531

Last Wednesday I ordered a couple of items from Enco for their 20% off and free freight special. However upon final checkout I was about $9.00 from being able to use the coupon codes for the 20% off and free freight. I hurried and remembered looking at a tool organizer for around $13.00 but didn't have it written down. I was going to build a small shelf on the side of my toolcart that I rebuilt and will reside next to my PM-932PDF when it arrives.

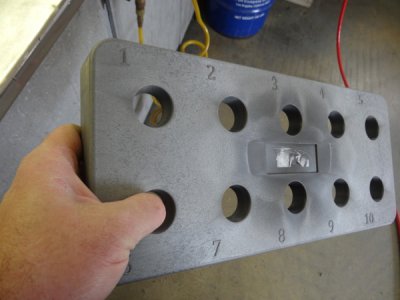

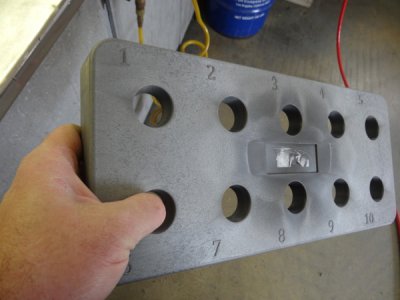

Here is the toolholder that I ordered from Enco.

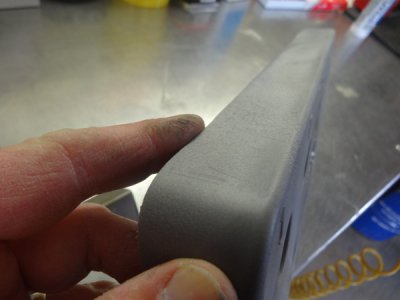

It actually had four legs that were part of the mold and this tool holder was designed to stand on a shelf rather than hanging. I simple cut the four legs off flush with the edge of the tool holder.

I then used some bent 12-gauge P&O to attach the tool holder to the underside of the cart. I marked and drilled three holes to attach the tool holder to the angle.

I tack welded the angle to the underside of the cart and then bolted the tool holder to the angle. I reinforced the plastic tool holder with some large fender washers and it seems pretty rigid.

Here it is completed.

Mike.

Here is the toolholder that I ordered from Enco.

It actually had four legs that were part of the mold and this tool holder was designed to stand on a shelf rather than hanging. I simple cut the four legs off flush with the edge of the tool holder.

I then used some bent 12-gauge P&O to attach the tool holder to the underside of the cart. I marked and drilled three holes to attach the tool holder to the angle.

I tack welded the angle to the underside of the cart and then bolted the tool holder to the angle. I reinforced the plastic tool holder with some large fender washers and it seems pretty rigid.

Here it is completed.

Mike.

- Joined

- Jan 11, 2013

- Messages

- 1,821

Re: Yesterday's POTD

Wow awesome angle plate!

Did you do the welding too? What did you use? That's an awfully thick plate, outside my abilities

Bernie

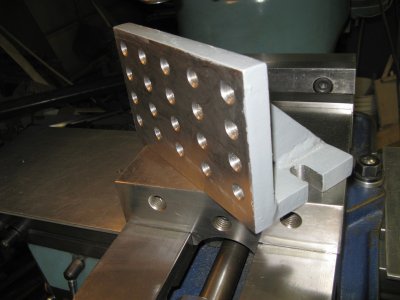

Here's a photo of an angle plate I fabricated to use on the mill.

It's 5x8 inches and tapped with 1/2 x 13 threads.

Wow awesome angle plate!

Did you do the welding too? What did you use? That's an awfully thick plate, outside my abilities

Bernie

Architard, that looks much better than the stock cattywompus HF setup. Just be careful with the stock cast plates. I hear they can shatter.

Yes the material I had mentioned includes some 1" steel plate to replace those cast iron plates. The newer model of this press has steel plates instead of cast ones, unfortunately I bought mine before the new model came out.

These are great mods.... I think you should start a thread with this as well as posting it here. I have one of these 20 ton shop presses too... And these all address my issues! Then we could all add to it in one place... What do you think?Bernie

That's a great idea, I was inspired by others to make the quick release t handle. I'll try to start a thread in the shop made tooling section for 20 ton shop press upgrades.