- Joined

- Apr 30, 2012

- Messages

- 2,401

today I worked on my Yulee sugar mill model some more..

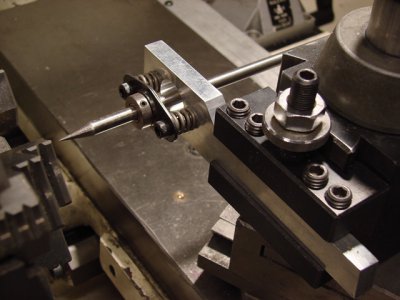

I installed the boiler feed pump and started the linkage parts.

the tap and screws are 0-80 and the packing box on the top of the pump is actually a separate piece.

steve

http://www.hobby-machinist.com/showthread.php?t=6463&p=201702#post201702

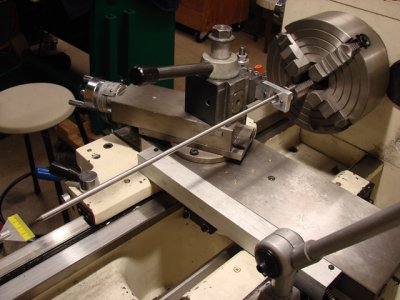

I installed the boiler feed pump and started the linkage parts.

the tap and screws are 0-80 and the packing box on the top of the pump is actually a separate piece.

steve

http://www.hobby-machinist.com/showthread.php?t=6463&p=201702#post201702