- Joined

- Dec 19, 2012

- Messages

- 41

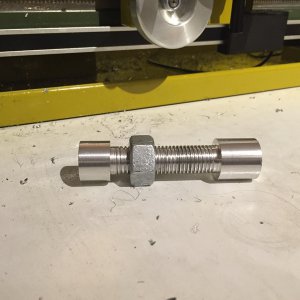

Looks like it will work, Savarin.

All plans for what I thought I'd do today have changed.

The refrigerator went on the blink yesterday. It's 25 years old and has had the defrosting coils replaced at least 3 times already. I have to put on my cammies and go hunting for a refrigerator, or decide to have it expensively fixed one more time.

When my last fridge died, I bought a new one and used the old one for a place to put cans of paint/ spray whatevers, added a couple of hasps, and a locking semi-flam locker was born