-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2016 POTD Thread Archive

- Thread starter sanddan

- Start date

- Joined

- Dec 27, 2014

- Messages

- 4,058

Great job, great description. That's what Hobby Machining is all about, If you need it, you can make it.

- Joined

- Feb 1, 2015

- Messages

- 9,621

I don’t know if gun blue will work on aluminum or not, if not I’ll Sharpie marker it black. Fits like a glove! Now just need a nice buck to walk in front of the scope . . .

[/ATTACH]

The blueing compound for steel won't work on aluminum. There is a blackening compound for aluminum.

http://www.redsgear.com/bw-casey-al...intid=303705&gclid=CJHQ4fnAktACFYKBaQodzqMBtQ

W

WMello

Forum Guest

Register Today

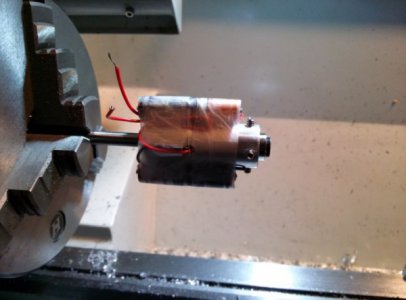

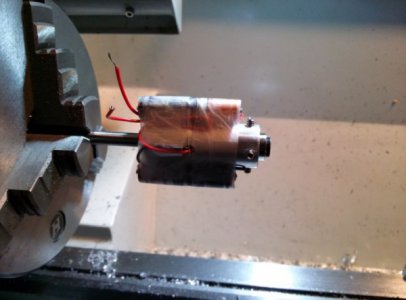

Need way to align two shaft bearings that are 6 feet apart, and mark glass plate in between for shaft hole. Here is the idea of a quick-and-dirty laser alignment device.

Cheap laser pointer, two batteries, aluminium tube, steel shank and four set screws.

The shank is ¼” OD; the same ID of the bearings

The inner end of the laser unit is held inside the aluminium tube by a o-ring.

Horrible picture...

Turning it on the lathe at about 200 RPM, it projects a circle on the far wall.

Adjusting the screws for a single laser dot.

Now the beam is aligned with the shank.

Insert the thing on one of the bearings. Adjust bearings for the beam to pass thru far bearing. Mark glass plate for hole.

Wagner

Cheap laser pointer, two batteries, aluminium tube, steel shank and four set screws.

The shank is ¼” OD; the same ID of the bearings

The inner end of the laser unit is held inside the aluminium tube by a o-ring.

Horrible picture...

Turning it on the lathe at about 200 RPM, it projects a circle on the far wall.

Adjusting the screws for a single laser dot.

Now the beam is aligned with the shank.

Insert the thing on one of the bearings. Adjust bearings for the beam to pass thru far bearing. Mark glass plate for hole.

Wagner

- Joined

- May 14, 2013

- Messages

- 237

Brownells also sells a baked on aluminum semi gloss / flat black for gun parts that is quite durable. PS nice work on the duplication of the scope cap.

- Joined

- Dec 22, 2015

- Messages

- 561

The handle on my wood stove has been getting looser and looser over time. There is an adjustment to compensate but that is all used up. So I pulled the handle from the stove and seen that the shaft on the handle was fine but the block it passes through is badly worn and so is the wedge shaped latch. The latch is made of steel but the block is made of brass and I don't have any. So I figured I would just order the part. Dealer tells me I have to buy the whole assembly and it comes with the block the latch and the handle. Cost ....... $85 plus taxes = $95. No way I'm paying that ......... I have a lathe and a mill. So I pull the assembly apart and take measurements of the block, shaft and latch.

I decided to just weld some steel onto the worn latch and just make a new block out of aluminum scraps that I previously melted down in my forge. If the aluminum isn't strong enough I guess I will make a new one out of steel or see if I can find some brass somewhere.

Here is a pic pic of the stock handle assembly on the stove.

The brass block. There sure isn't much meat left on the shaft opening nor is there much on either side of the screw holes that hold it onto the door. I should have noticed that before I started making the new one. The face in front is on a 5* angle to the rest of the block, to allow for the angle of the door edge, where it mounts.

Here is a pic of the installed new block. I should have taken pics of the process but forgot. I should've also rounded the edges but this is in my shop so I'm the only one that will see it. If it was in the house I would have to make it nicer for the wife.

I also finished making and mounting the drawer faces on my lathe stand. I decided not to paint them because the natural grain of the wood is much nicer to look at. Well for now anyways, until I get my grubby hands all over them. I like the way the stand and drawers turned out and I really like having all the lathe tools, measuring devices, etc. at hand. I like it so much I'll probably end up making something similar for the new lathe that's on it's way and for the mill / drill, just so I have all my tools handy instead of laying all over the floor and a bench that's 20 ft away.

I decided to just weld some steel onto the worn latch and just make a new block out of aluminum scraps that I previously melted down in my forge. If the aluminum isn't strong enough I guess I will make a new one out of steel or see if I can find some brass somewhere.

Here is a pic pic of the stock handle assembly on the stove.

The brass block. There sure isn't much meat left on the shaft opening nor is there much on either side of the screw holes that hold it onto the door. I should have noticed that before I started making the new one. The face in front is on a 5* angle to the rest of the block, to allow for the angle of the door edge, where it mounts.

Here is a pic of the installed new block. I should have taken pics of the process but forgot. I should've also rounded the edges but this is in my shop so I'm the only one that will see it. If it was in the house I would have to make it nicer for the wife.

I also finished making and mounting the drawer faces on my lathe stand. I decided not to paint them because the natural grain of the wood is much nicer to look at. Well for now anyways, until I get my grubby hands all over them. I like the way the stand and drawers turned out and I really like having all the lathe tools, measuring devices, etc. at hand. I like it so much I'll probably end up making something similar for the new lathe that's on it's way and for the mill / drill, just so I have all my tools handy instead of laying all over the floor and a bench that's 20 ft away.

- Joined

- Mar 25, 2013

- Messages

- 4,617

In my shop today I had an epiphany! Ya'll probably know this already....If you take the 1/4 of the RPM you are running at, x the diameter of your workpiece you are very close to SPFM. I never thought about it that way before. I can do that in my head pretty quick.

Robert

Robert

- Joined

- Feb 17, 2013

- Messages

- 336

A little more progress on my XS650 project. I glass bead blasted the 19" wheels and drilled each spoke with 5 evenly spaced holes and powder coated them in a cast aluminum color finish. I mounted a couple of Shinko 241 tires that resemble the old Dunlop Trials Universal tires that came on Yamaha Enduros in the 70's, both in 3.50" X 19" size. I'm thinking about front fender options now and leaning toward a plastic dual sport fender. I took the one off my DRZ400 (21" front wheel) and temporarily attached it with zip ties. It looks pretty good so I ordered a black UFO fender for a Honda CR85 that will fit better with the 19" wheel. This weekend I'm going to work on an exhaust system and test my TIG welding skills.

Last time Dime City had a free shipping deal I ordered a TC Bros exhaust kit from them. Nice quality mandrel bends and header flanges for the money.

I've decided to go with a left side high pipe system something like my Honda CL450 has, I'm a sucker for high pipes!

My TIG welding skills are pretty weak so I decided to MIG weld all the pipe joints and then dress the welds down with a flap wheel and polish them with a Roloc disc. I spent a few hours in the garage today and came up with this for head pipes. The mild steel is easy to work with and if it turns out OK I will probably get it ceramic coated.

I cut some 1" square tubing into a couple of C shaped bracket and TIG welded some 1/4" nuts to the inside, then TIG welded these bracket to the inside of the head pipes for support and also to serve as a front mount for a heat shield I will build later.

I'm working on an idea for a single muffler that will involve a 1' section of 4" exhaust pipe with machined aluminum end caps. I roughed out the idea like this.

To be continued.

Last time Dime City had a free shipping deal I ordered a TC Bros exhaust kit from them. Nice quality mandrel bends and header flanges for the money.

I've decided to go with a left side high pipe system something like my Honda CL450 has, I'm a sucker for high pipes!

My TIG welding skills are pretty weak so I decided to MIG weld all the pipe joints and then dress the welds down with a flap wheel and polish them with a Roloc disc. I spent a few hours in the garage today and came up with this for head pipes. The mild steel is easy to work with and if it turns out OK I will probably get it ceramic coated.

I cut some 1" square tubing into a couple of C shaped bracket and TIG welded some 1/4" nuts to the inside, then TIG welded these bracket to the inside of the head pipes for support and also to serve as a front mount for a heat shield I will build later.

I'm working on an idea for a single muffler that will involve a 1' section of 4" exhaust pipe with machined aluminum end caps. I roughed out the idea like this.

To be continued.

- Joined

- May 16, 2016

- Messages

- 1,698

Click upload file, find the picture, after it uploads, click thumbnail or full image it's super super super easy

I have trouble opening pictures that are thumbnail only, I'm running win 10 and everything is working ok, but I just can't open pictures that display as thumbnail, they all have a red X on them. Any clues for me?

- Joined

- Feb 27, 2014

- Messages

- 2,130

To be continued.

John, Awsome bike build. Thanks for the great pics