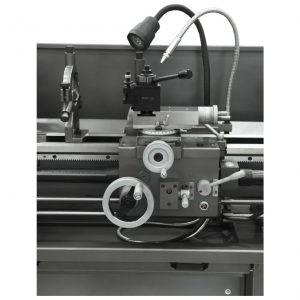

The back gears make no difference in the amount of feed, the feed gear train is driven by the spindle. Whole nimbers on the threading / feeding chart are threads per inch, feeds would be expressed as fractions of an inch. I note that on the lathe pictured, there is a lever at the lower right that is set for threads or feeds (to the right position), this would slow down the feed rate. Also, I see that the feed rate is not stated, so one would have to figure it out somehow, related to the thread rate, I.