- Joined

- Nov 22, 2022

- Messages

- 387

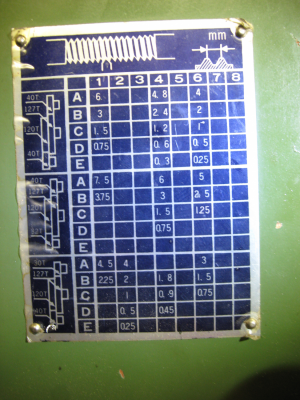

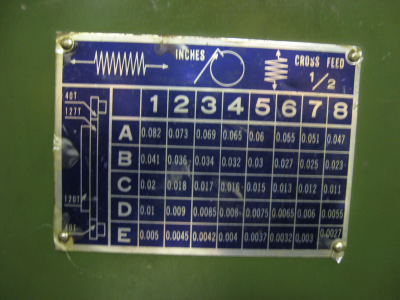

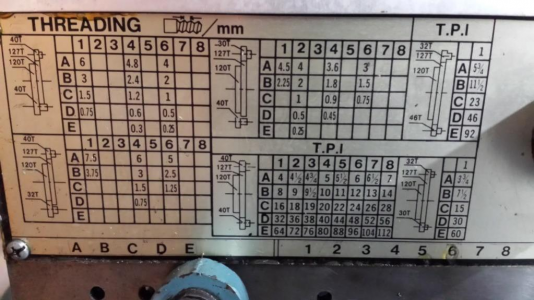

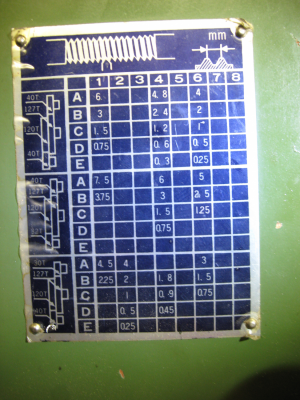

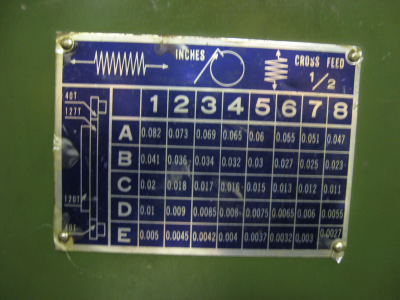

Put up a pic of your threading chart, That will show what gears were included with the lathe and the orientation of them for whatever threading you plan on doing.

Who knows, It may show a 24 tooth gear. Here is a couple of an Enco, Which I believe is what you have.

These 2 pics show 40 tooth gears and the 30 and 32 tooth gears.

Who knows, It may show a 24 tooth gear. Here is a couple of an Enco, Which I believe is what you have.

These 2 pics show 40 tooth gears and the 30 and 32 tooth gears.