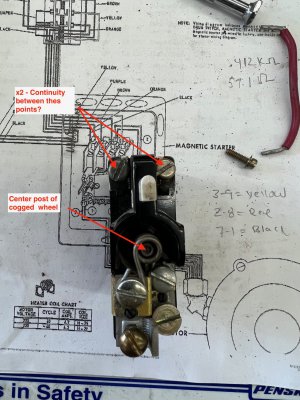

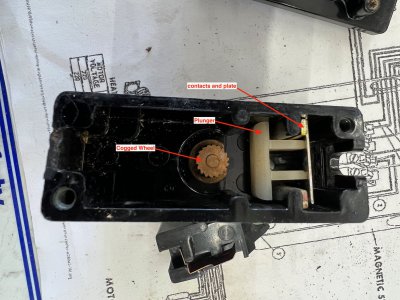

Could you explain to me how the overloads work?. I was not getting power to the jumpers on the top side of the overloads, so i took them apart to see how they work. It seems the x2 wire is one side of a contact and theres a metal plate that bridges each side of the contact to feed power across to the other thermal overload top section via jumper wires. Below that and separated by a plastic plunger, the metal cogged wheel that is attached to a post that goes in the middle of the coiled wire (reed wire?) between the terminals Of the overload. Over the cogged wheel is a plastic component with a copper pawl that contacts the cogged wheel. I assume that when the thermal overload melts, the spring pressure behind this part allows this pawl to turn the cogged wheel and push the plunger to disengage the upper contact plate stopping power from transferring from x2 to the the other side and thus the other overload.Sorry for the delay getting back. Let's try some checks to figure out where we're losing the voltage. With power on and drum switch on check between coil wire V and red wire X2 on the left overload. If you have 240V we're pretty sure it's wired correctly. Then move probe off X2 and on to wire that goes between the overloads. If you lost voltage then the left overload is tripped or bad. If you still have 240V move the probe to the reed wire on the right of the right overload (should be the wire that goes down to coil wire W). If you lost the 240V then the right overload is tripped or bad. If the right overload is the issue, with the power off, you can try to reset it by pushing in the broken plunger with a small screw driver or punch. It can also be stuck too far in when it was broken so you can try tapping it with whatever tool quickly to see if it will bounce out. Also if you could get a few pics of different angles on how it's wired now.

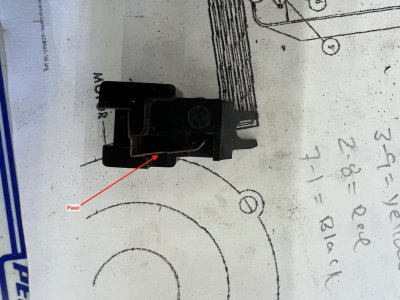

Assuming i understand this correctly, if the overload is good there should be continuity between x2 and the screw tap to its right. The lower terminal should have continuity between all of the taps above and below the coiled wire. Internally i see no relationship between the upper x2 tap and the lower wire attachment, only the spring pressure to push the plunger and separate the upper x2 contact points if the coiled spring were to melt. Sorry if this is obvious or completely off base. I’m trying to understand the concept. Upon reassembly, i assume after the springs are inserted, i should pull the pawl back to allow the upper contact plate to bridge the x2 and jumper terminal?