- Joined

- Jun 7, 2019

- Messages

- 151

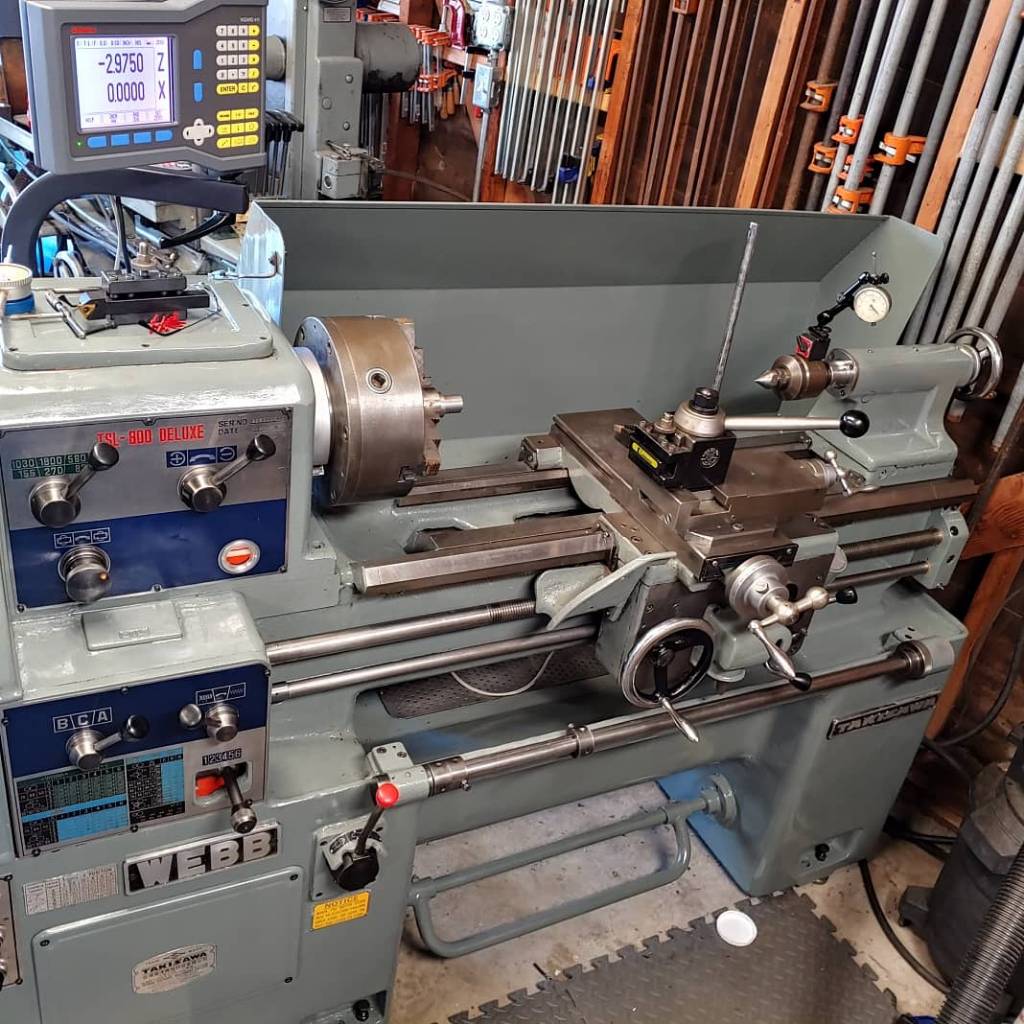

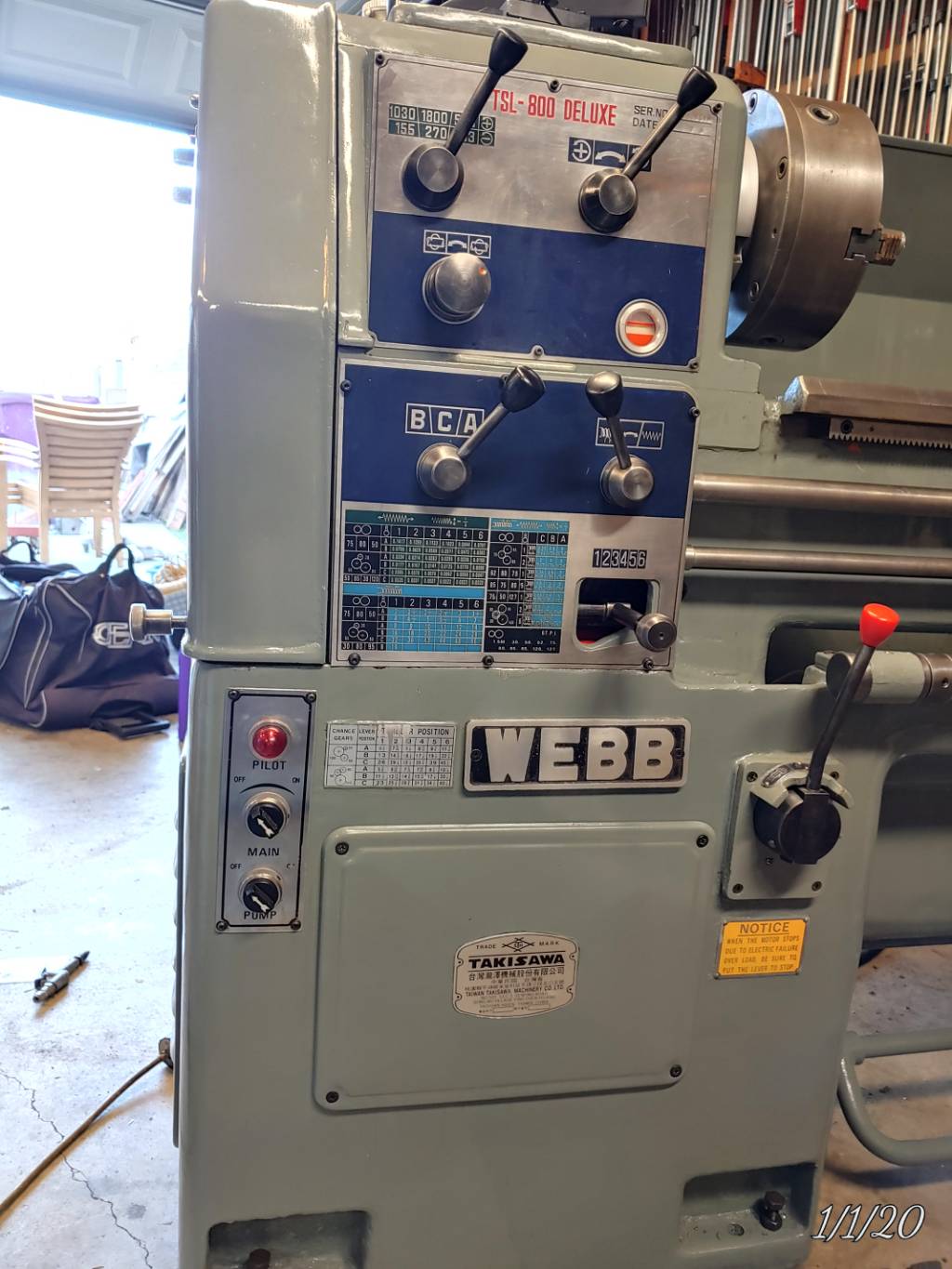

Yeah, the 2 speed version of our lathe is on Craigslist here for Ave price. It would be cool but im sure I'll live without it.Our lathes look identical. I notice some have more speeds, I guess they have a two speed motor. So far this speed range does everything I’ve needed.