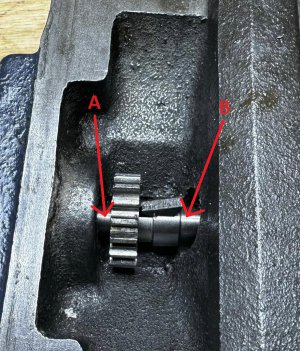

Because of how/where I found that squared foam-like thingy in there, I asked Logan for where the felt washers needed to be... I thought that it was one on each side of the gear... does not look like that is the case. Here is the respond that I got:

"The felts go behind the gear. In fact, it's the only place they CAN go, since the near side of the gear is directly up against the crossfeed bushing.

Keep the felts well oiled; it will leach out onto the screw. They also help (a little) in keeping swarf away from the gear."

And further asked to make sure I was clear on the comment... Logan Lathe thank you for the prompt response. Just to further clarify, both washers go on the same side? And can you confirm what is the rear of the gear? A or B?

"Logan Lathe - in the "B" position, or on the Acme threaded side. Between the gear and the crossfeed nut."

I ordered both the gear and felt washers... once those arrive, I will put it all back together.

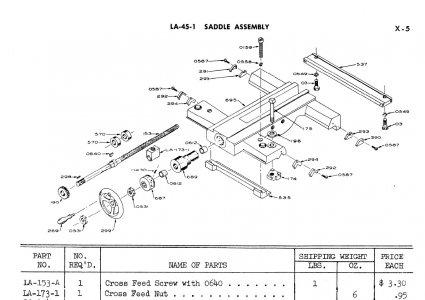

2 - Felt washers (LA-570) -

new part number LP-1367

1 - Crossfeed Gear, 16T (LA-190) -

new part number LP-1115

Only thing that is holding me back from calling it all done, is the correct wiring of the switch, so I have forward and reverse. When I am ready for that, I will ask for guidance.