- Joined

- Oct 4, 2011

- Messages

- 727

Wow, I'm jealous of that telescope...

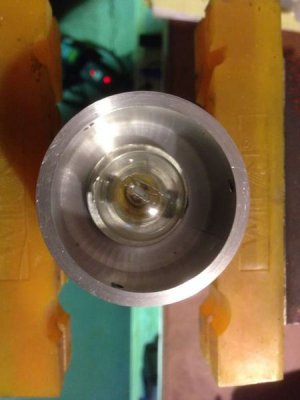

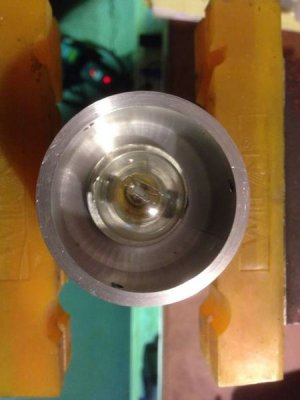

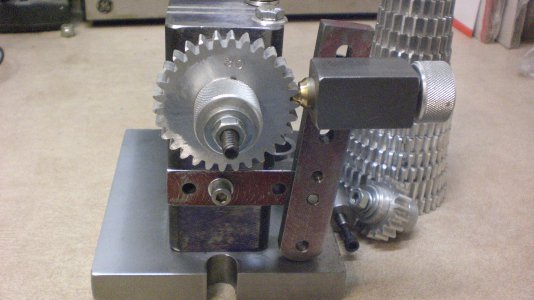

Nothing fancy from me, but they function well as tail/brake lights for motorcycles. They start life as 6061 on my hacksaw by Millers Falls (patented 1893!), bulk done on the South Bend 9B and usually finish up with some hand files and the drill press. Simple but effective. The lenses are off vintage cars from the 30's to the 50's found online at random.

I am always inspired seeing the projects done by you folks here - and although the lights are very basic projects, I have applied much of what I have learned here into these, and it's nice to see the work riding down the road when you're finished....

These are really good. Where did you get the lenses? Are they glass or plastic? What does the inside look like, LED or incandescent? Please post more pictures of these.

Jeff