- Joined

- May 7, 2023

- Messages

- 1,332

I have lusted after machine tools since 9th grade shop when I made a working cannon, and much to my shop teachers dismay set off all of the car alarms in the neighborhood with it outside of the shop doors in the faculty parking lot. He thought this was impossible for a kid like me, but I had made other cannons and hadn't blown my fingers off yet. I showed him I could do it, and he gave me an A for the semester.

I always wanted some of the precision made German, Checz or Japanese models, but these were always very expensive and the lower quality ones just didn't do it for me. I had been looking for a benchtop lathe recently as, while I have access to larger machines and in fact have a whole machine shop worth of tools, these small machines fit in well with my hobbies. I liked the Taig lathes, and the Unimat lathe is just so tiny and cute (Fits in a briefcase), but I could just never pull the trigger on one as even used their still $600-700.

Then I ran across an ad on FB market for this Prazi SD300 (Also sold under different names Hobbymat, Shop&Sohn, Prazimat) with the hard to find milling head and called the guy up. He mentioned in passing that there was another smaller lathe included and everything was brand new.

I couldn't get in the truck fast enough.

Thread here.

So some background as to why I'm so stoked about this. This lathe in particular (The whole line really) has intrigued me for much of my adult life. Having read everything I could in model engineering and live steam magazines in the 90s while serving my apprenticeship as a Tool&Die maker I wanted badly to own one knowing how good they were (Vicariously through the writings of others like me), but the $1500 price tag (in 1990 dollars) put them far out of reach.

I had seen them, seen them in use and even got laughed at by my 4th year apprenticeship instructor for wanting to own the CNC version we had at school we never got to use. I later found out he didn't know G code and couldn't operate it, so he scoffed instead.

These were engineered and in made in east Germany and sold at a loss abroad so they could have access to US dollars as their political and monetary system was crap both before and after the fall of the Berlin wall. The extreme high quality was the only way these would sell and while very expensive for a person to buy, universities, R&D labs and medical manufacturers bought them happily. They are far from a toy like you find in some other mentioned offerings and were much more well made than anything in their class.

So here's what were talking about. This was the day I brought it home along with some assorted tooling I got with it.

Looking closely you can see the two lathes a Prazi SD300 and an MD200 Miniturn, and the milling head attachment in the upper right.

First lets deal with the lathe.

Now you're probably thinking "New? that thing is a friggin mess!", and yeah, it was. The pervious owner had it in storage and sprayed it with cosmoline to prevent it from rusting.

IMO he did too good of a job as this **** was a mess to clean off and Ill probably be cleaning and disassembling and cleaning some more to get rid of all of it.

All of that brown, cream and rust colored **** is what I had to remove and its sticky, stinky and nothing will touch it save for copious amounts of acetone. Even then it does not want to come off.

This is what 10min of scrubbing with a stiff plastic brush soaked with acetone, followed with an acetone soaked paper towel removed.

Its just everywhere and would wad up in little balls where you had to push it around and form a blob to remove it.

Rinse and repeat until completed.

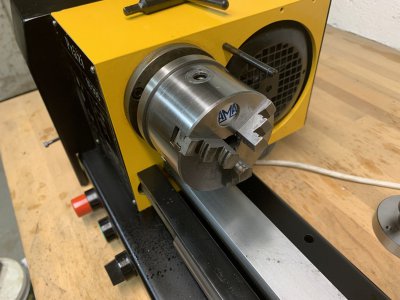

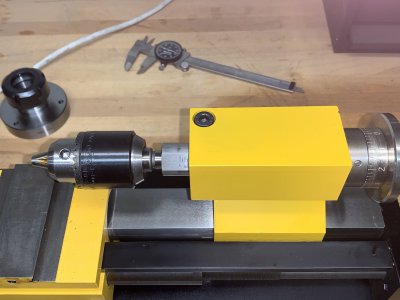

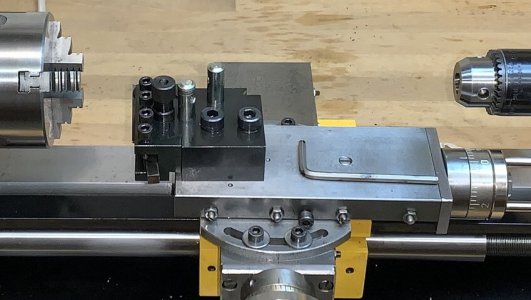

This is what it looks like today after three days of cleaning, about 4hrs total.

I have the chuck and cross slide removed, cleaned, oiled and stored for reassembly when I get it into a permanent spot. Once I get it moved Ill reassemble it all, but for now its staying in pieces to make it easier to move.

Under all that crap the surface looks nearly new with only light staining. This is one of the worst stained spots.

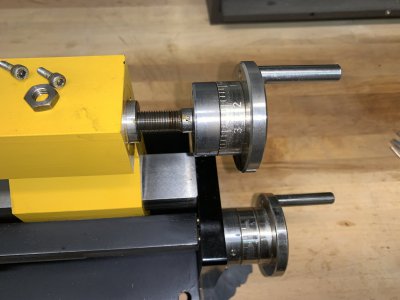

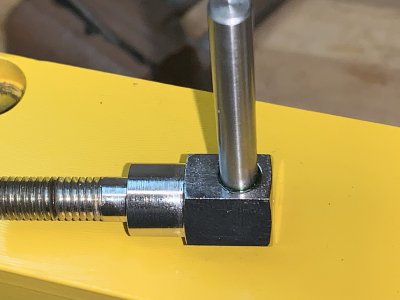

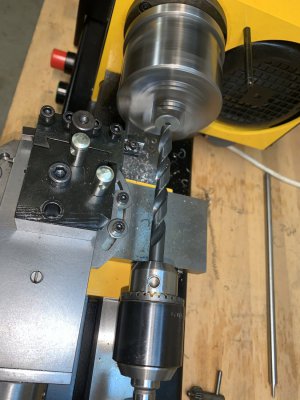

So the first order of business now that its clean enough to work on is removing a broken bolt that held the feed engage lever. This lever allows both power feed and threading via a set of change gears. I wanted to fix it first so I could move the saddle under power to clean the places I couldn't get to and also to generously lubricate everything including the lead screw to further remove any cosmoline residue.

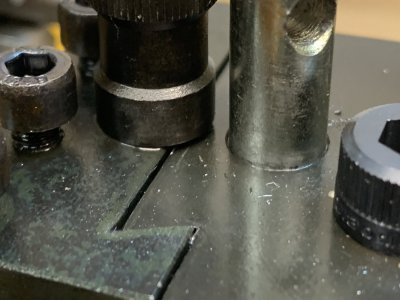

So here's the screw broken off nearly flat. Before drilling and using an easy out on this tiny screw (4MM?) I decided to try and coax it out with a sharpened tap and a hammer.

What you do is using something harder than the bolt/screw (I like a 10-32 tap) and you grind a fine point on it. Not too fine or it will break off and just chisel away material, but not to blunt or it wont bite. The angle you hold the tap at is critical and you have to constantly go in circular motion, tapping and judging the process as you go.

A little work and it stands proud of the surface and can be grabbed with pliers or even your fingers if its not bound up.

All fixed up with a new screw in place for now. Ill make some kind of handle for this as one of its first jobs.

You can see the piece of broken screw that was removed laying on the table.

So for now Ill finish up with a short list of items I want to make or add to the machine to make it more user friendly.

It needs a micrometer carriage stop.

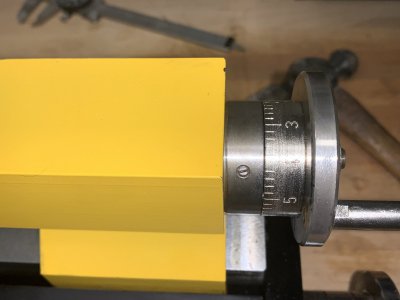

A set of linear scales. The handwheel dials are tiny and not to big around which lends to inaccuracy's in reading and or turning/stopping them to get precise depth of cuts.

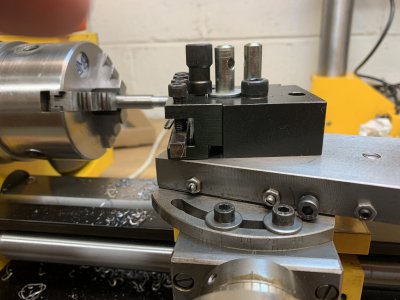

A quick change Aloris style tool post. This I may source or if I cant find what suits this machine Ill make it.

A chip tray and back splash are going to be a must.

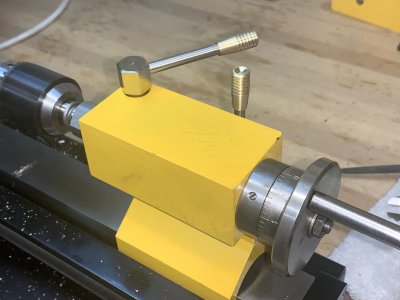

And finally Ill make a copy of the low speed kit you can buy for these. This kit gives you two lower than stock speeds for threading and tapping or other delicate procedures.

I always wanted some of the precision made German, Checz or Japanese models, but these were always very expensive and the lower quality ones just didn't do it for me. I had been looking for a benchtop lathe recently as, while I have access to larger machines and in fact have a whole machine shop worth of tools, these small machines fit in well with my hobbies. I liked the Taig lathes, and the Unimat lathe is just so tiny and cute (Fits in a briefcase), but I could just never pull the trigger on one as even used their still $600-700.

Then I ran across an ad on FB market for this Prazi SD300 (Also sold under different names Hobbymat, Shop&Sohn, Prazimat) with the hard to find milling head and called the guy up. He mentioned in passing that there was another smaller lathe included and everything was brand new.

I couldn't get in the truck fast enough.

Thread here.

So some background as to why I'm so stoked about this. This lathe in particular (The whole line really) has intrigued me for much of my adult life. Having read everything I could in model engineering and live steam magazines in the 90s while serving my apprenticeship as a Tool&Die maker I wanted badly to own one knowing how good they were (Vicariously through the writings of others like me), but the $1500 price tag (in 1990 dollars) put them far out of reach.

I had seen them, seen them in use and even got laughed at by my 4th year apprenticeship instructor for wanting to own the CNC version we had at school we never got to use. I later found out he didn't know G code and couldn't operate it, so he scoffed instead.

These were engineered and in made in east Germany and sold at a loss abroad so they could have access to US dollars as their political and monetary system was crap both before and after the fall of the Berlin wall. The extreme high quality was the only way these would sell and while very expensive for a person to buy, universities, R&D labs and medical manufacturers bought them happily. They are far from a toy like you find in some other mentioned offerings and were much more well made than anything in their class.

So here's what were talking about. This was the day I brought it home along with some assorted tooling I got with it.

Looking closely you can see the two lathes a Prazi SD300 and an MD200 Miniturn, and the milling head attachment in the upper right.

First lets deal with the lathe.

Now you're probably thinking "New? that thing is a friggin mess!", and yeah, it was. The pervious owner had it in storage and sprayed it with cosmoline to prevent it from rusting.

IMO he did too good of a job as this **** was a mess to clean off and Ill probably be cleaning and disassembling and cleaning some more to get rid of all of it.

All of that brown, cream and rust colored **** is what I had to remove and its sticky, stinky and nothing will touch it save for copious amounts of acetone. Even then it does not want to come off.

This is what 10min of scrubbing with a stiff plastic brush soaked with acetone, followed with an acetone soaked paper towel removed.

Its just everywhere and would wad up in little balls where you had to push it around and form a blob to remove it.

Rinse and repeat until completed.

This is what it looks like today after three days of cleaning, about 4hrs total.

I have the chuck and cross slide removed, cleaned, oiled and stored for reassembly when I get it into a permanent spot. Once I get it moved Ill reassemble it all, but for now its staying in pieces to make it easier to move.

Under all that crap the surface looks nearly new with only light staining. This is one of the worst stained spots.

So the first order of business now that its clean enough to work on is removing a broken bolt that held the feed engage lever. This lever allows both power feed and threading via a set of change gears. I wanted to fix it first so I could move the saddle under power to clean the places I couldn't get to and also to generously lubricate everything including the lead screw to further remove any cosmoline residue.

So here's the screw broken off nearly flat. Before drilling and using an easy out on this tiny screw (4MM?) I decided to try and coax it out with a sharpened tap and a hammer.

What you do is using something harder than the bolt/screw (I like a 10-32 tap) and you grind a fine point on it. Not too fine or it will break off and just chisel away material, but not to blunt or it wont bite. The angle you hold the tap at is critical and you have to constantly go in circular motion, tapping and judging the process as you go.

A little work and it stands proud of the surface and can be grabbed with pliers or even your fingers if its not bound up.

All fixed up with a new screw in place for now. Ill make some kind of handle for this as one of its first jobs.

You can see the piece of broken screw that was removed laying on the table.

So for now Ill finish up with a short list of items I want to make or add to the machine to make it more user friendly.

It needs a micrometer carriage stop.

A set of linear scales. The handwheel dials are tiny and not to big around which lends to inaccuracy's in reading and or turning/stopping them to get precise depth of cuts.

A quick change Aloris style tool post. This I may source or if I cant find what suits this machine Ill make it.

A chip tray and back splash are going to be a must.

And finally Ill make a copy of the low speed kit you can buy for these. This kit gives you two lower than stock speeds for threading and tapping or other delicate procedures.

Last edited:

![IMG_2990[1].jpg IMG_2990[1].jpg](https://www.hobby-machinist.com/data/attachments/411/411835-65cf01f8eaa171c6c30bf1ff16365569.jpg)

![IMG_2989[1].jpg IMG_2989[1].jpg](https://www.hobby-machinist.com/data/attachments/411/411836-9c2a6db122349cb959b7a0668e764737.jpg)

![IMG_2983[1].jpg IMG_2983[1].jpg](https://www.hobby-machinist.com/data/attachments/411/411837-a475d29fbc428be89c7b6238cd71ee0b.jpg)

![IMG_2985[1].jpg IMG_2985[1].jpg](https://www.hobby-machinist.com/data/attachments/411/411839-54c63c18eb58a2261e7fb2605830189d.jpg)

![IMG_2986[1].jpg IMG_2986[1].jpg](https://www.hobby-machinist.com/data/attachments/411/411838-ee4bb988e1e836b433db207a412f7e2a.jpg)

![IMG_2988[1].jpg IMG_2988[1].jpg](https://www.hobby-machinist.com/data/attachments/411/411840-bd3b7cb02fb1dd1f21647822e217a576.jpg)

![IMG_2991[1].jpg IMG_2991[1].jpg](https://www.hobby-machinist.com/data/attachments/411/411841-e79dc0b22e6b2d0dde3cffb77f92e021.jpg)