- Joined

- May 7, 2023

- Messages

- 1,332

Well I made some miscalculations.

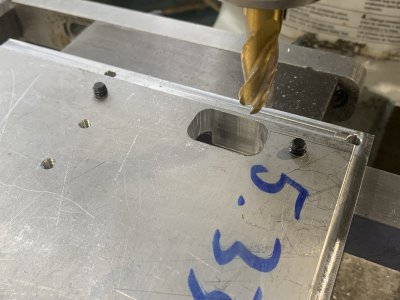

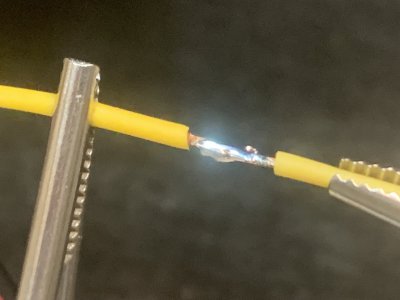

The controller plug wouldn’t fit through my finely crafted and deburred cable slot.

Simple enough to fix, but much harder to deburr with the new keyhole shape. I simply took a 1/4" endmill and made a half moon cutout so the latch on the plug could fit through and that was that.

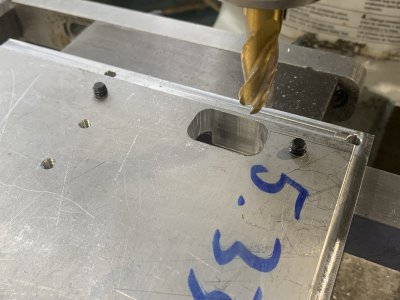

Next I had to bolt the arm to the motor plate and mill a "Correctly sized" opening in the two for the wires to pass through. I wasn't being picky about the size of the slot this time as I had plenty of room on this end and I also had to fish the wires out of the hollow extension arm, and too small of a slot would make that more difficult than needed.

So once I had them properly positioned and bolted together I cut the slot for the wires by making a series of overlapping cuts with an endmill.

Then I opened this up to match the inner dimensions of the tube.

And deburred it with a countersink.

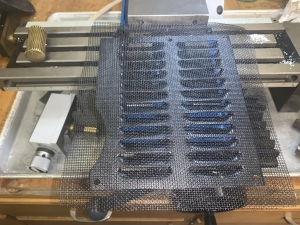

And finally you can see everything together as it will be installed.

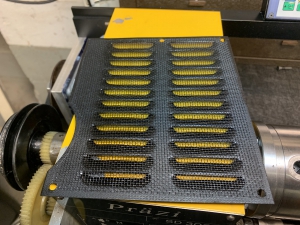

Once I got this all home I painted it with semi gloss black to match the rest of the black parts of the lathe. I got it all installed, stood back and was actually a bit disappointed by what I saw.

It looks like it came from the factory this way.

I mean, it fits and functions perfectly, but I was expecting it to stand out more or something, to look more custom.

Not blend right in like it was made this way.

Oh well, I guess I did a good job.

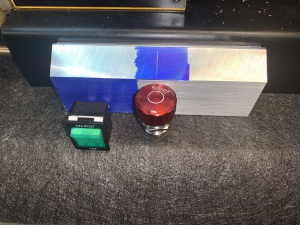

I still have to make another panel to go on the front where the three holes from the stock controls were. This will house the custom Crafter breaker switch and an E stop button for turning the machine on and off and of course acting as an E stop.

Now that it is installed in its final configuration I was able to do a little more testing. I did away with my shop made pully, and decided I would use the factory pully for now. Ill also remake an exact copy out of aluminum in the near future. The factory one is really bad com-bloc Bakelite which wasn't very concentric to begin with, that only got worse when I chucked it up on our Hardinge lathe and bored out the hole to fit the 15mm motor shaft.

It works for the time being and testing revealed these speeds.

Back gear speeds

L1 35 - 420rpm

L2 67 - 825rpm

High gear

H1 140 - 1550rpm

H2 270 - 2750rpm

With the availability of both high and low range and the wide speed range from the drive system, I'm more than happy with how this turned out. Im thinking Ill probably use it most in L2 as that seems to be the best combination of speed and power while letting the motor rev freely enough to keep it happy and cool.

I took a short video of it taking a .040r (.080 total) deep cut. This started at 35RPM and it goes up to 420RPM and it cut really well within that whole range.

This is 3/8" O-1 tool steel.

Thought I would also point out that there is 1-3/4" - 2" of sickout on that piece of 3/8" O-1 with little deflection, a testament to how nice that little chuck is.

The controller plug wouldn’t fit through my finely crafted and deburred cable slot.

Simple enough to fix, but much harder to deburr with the new keyhole shape. I simply took a 1/4" endmill and made a half moon cutout so the latch on the plug could fit through and that was that.

Next I had to bolt the arm to the motor plate and mill a "Correctly sized" opening in the two for the wires to pass through. I wasn't being picky about the size of the slot this time as I had plenty of room on this end and I also had to fish the wires out of the hollow extension arm, and too small of a slot would make that more difficult than needed.

So once I had them properly positioned and bolted together I cut the slot for the wires by making a series of overlapping cuts with an endmill.

Then I opened this up to match the inner dimensions of the tube.

And deburred it with a countersink.

And finally you can see everything together as it will be installed.

Once I got this all home I painted it with semi gloss black to match the rest of the black parts of the lathe. I got it all installed, stood back and was actually a bit disappointed by what I saw.

It looks like it came from the factory this way.

I mean, it fits and functions perfectly, but I was expecting it to stand out more or something, to look more custom.

Not blend right in like it was made this way.

Oh well, I guess I did a good job.

I still have to make another panel to go on the front where the three holes from the stock controls were. This will house the custom Crafter breaker switch and an E stop button for turning the machine on and off and of course acting as an E stop.

Now that it is installed in its final configuration I was able to do a little more testing. I did away with my shop made pully, and decided I would use the factory pully for now. Ill also remake an exact copy out of aluminum in the near future. The factory one is really bad com-bloc Bakelite which wasn't very concentric to begin with, that only got worse when I chucked it up on our Hardinge lathe and bored out the hole to fit the 15mm motor shaft.

It works for the time being and testing revealed these speeds.

Back gear speeds

L1 35 - 420rpm

L2 67 - 825rpm

High gear

H1 140 - 1550rpm

H2 270 - 2750rpm

With the availability of both high and low range and the wide speed range from the drive system, I'm more than happy with how this turned out. Im thinking Ill probably use it most in L2 as that seems to be the best combination of speed and power while letting the motor rev freely enough to keep it happy and cool.

I took a short video of it taking a .040r (.080 total) deep cut. This started at 35RPM and it goes up to 420RPM and it cut really well within that whole range.

This is 3/8" O-1 tool steel.

Thought I would also point out that there is 1-3/4" - 2" of sickout on that piece of 3/8" O-1 with little deflection, a testament to how nice that little chuck is.

Attachments

Last edited:

![IMG_3706[1].JPG IMG_3706[1].JPG](https://www.hobby-machinist.com/data/attachments/424/424454-6edaffd218d26a90164a8bd4baa20d2c.jpg)

![IMG_3709[1].JPG IMG_3709[1].JPG](https://www.hobby-machinist.com/data/attachments/424/424455-5f4017c6db75981d46a9e65065a4bd8b.jpg)

![IMG_3710[1].JPG IMG_3710[1].JPG](https://www.hobby-machinist.com/data/attachments/424/424456-031bd0995585c5bf56fb02d958c40a44.jpg)

![IMG_3703[1].JPG IMG_3703[1].JPG](https://www.hobby-machinist.com/data/attachments/424/424457-4af68b2cb051e43ff074625f65974aff.jpg)

![IMG_E4032[1].JPG IMG_E4032[1].JPG](https://www.hobby-machinist.com/data/attachments/437/437228-6252cf63ca09d412b5c76a5eaf642576.jpg)

![IMG_E4033[1].JPG IMG_E4033[1].JPG](https://www.hobby-machinist.com/data/attachments/437/437229-5009747d21e2918a561df20a67597993.jpg)

![IMG_E4038[1].JPG IMG_E4038[1].JPG](https://www.hobby-machinist.com/data/attachments/437/437231-466490be6bf61ee9568ce5dc1360dee7.jpg)