So I have learned a great many things.

And, thanks for all the helpful thinking.

There is no second vee. More surprisingly, to my untrained eyes, is that Vevor is all-in on the jaunty-angle approach to bed seating: both the cross-slide and even the headstock sit on the vee/bed in the same way, though in both cases the far end has been machined to be relatively flat to the bed, and therefor have some meaningful bearing on it (the tailstock has no such machining, and so sits on the bed on the single outside edge of the casting, against the center of the bed).

Headstock (easiest to see the machining):

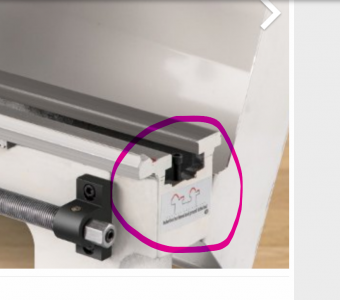

Cross-slide (hard to see behind those little plates: are those intended to keep chips out of the way?):

Here's the beginning of my current working solution: turn that casting around and let it bear fully on the ways; build a new vee out of 2 45 plates (I have limited precision tooling, or perhaps patience); after it's all set up right (have to flatten some sides) bolt it on with loctite between the plats and between them and the casting, so the loctite is taking any shear forces, the bolts are just keeping things together:

I'm drilling the holes in the plates oversized to allow for a bit of adjustment, and in the wrong places to keep me humble (hence the second bolt doesn't go in). It turns out that the other features of the casting are either symmetrical or easily duplicated.

I expect to keep the lathe, which is a good thing since I've drilled and tapped two holes in that casting! I think cheap mini-lathes are just like this, so I'll take a while to fix it up and see how much smoother/better I can get it. Many screws and such are loose on it, but that's just requiring me to learn it inside & out...

I'm curious about checking the axial alignment of the headstock shaft with the bed, I haven't quite figured out the right way to do that... I suppose ideally such an effort would also reveal flatness & twist... I'm thinking a crossline laser module in the chuck, like this one

https://www.amazon.com/gp/product/B07L4225TM/ref=sw_img_1?smid=A17O8U969TLM8D&psc=1,

I suspect that most of the things I do on this will be in plastic, aluminum, maybe brass... and that most of my projects will not require aerospatial precision. Like, before I even opened it I realized that a belt sander I am rebuilding requires bearings with external snap-ring grooves: on quick inspection I can't find them anywhere (yes, they are probably out there somewhere...). But now I can just cut a little snap ring groove into a standard bearing (yes, weakening it: that's what they did though). I mean, we'll see how all that goes should I ever get that far.

So far so fun!

btw: this is sort of proof-of-concept. I will come back and mill those properly, or at least flatten the pertinent sides, someday. After I move those pesky holes. Anyone know how to remove a misplaced hole?

Keith