Those are some pretty tough requirements, especially if you want to do multiple motor controls. If I had not started down the path that I am on, I would probably go with a cheap low power PWM controller and add the proper MOSFET and power supply for driving a high power motor.

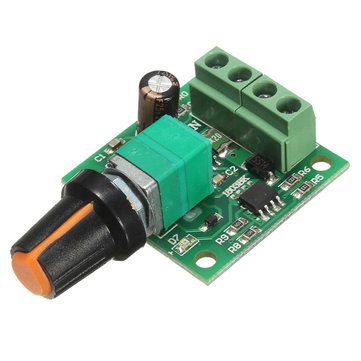

Here is an example:

Only US$2.99, buy best low voltage dc 1.8v 3v 5v 6v 12v 2a motor speed controller pwm 1803b sale online store at wholesale price.

www.banggood.com

This does pretty much what my controller would do for little more than the cost of the pot. Instead of driving the motor directly, I would drive an external MOSFET .

Add a 200v 20 amp bridge, a filter capacitor, and a power MOSFET and you're almost home. Yes it does require some work to maker a complete package but if you are making a bunch of them, you would have the advantage of having the same controller design for all your motors instead of a hodge podge of different controllers.

Heck, I might just order a couple for myself just to play with them.

My idea of a (near) perfect PWM controller would have some feedback from an encoder to provide rock solid speed control regardless of load, over current (stall) protection, and variable acceleration/deceleration. This in addition to return to preset speed and reversing, all with low EMI.

That is a future project though. My immediate goal is to have a basic functional VSD for my d.c. lather motor.