- Joined

- Jan 2, 2014

- Messages

- 8,862

If this doesn't get me beat up after school - nothing will.

Wait.

What route home do you use?

-brino

If this doesn't get me beat up after school - nothing will.

Thinking about this, there's a problem.

Seems to me to be a heck of a deal for $70. Cost more than that to fab one from scratch.Continuing the saga of restoring the GMC motorhome I now needed to extend the valve shafts for the sewer and gray water tanks.

They're threaded 1/4-20 I've used the Ace die stock with the 'pseudo guides' many times, and often get the die stock mis-aligned with the round stock I'm threading, thereby cutting a progressively worse alignment as the thread progresses. If it was larger stock I'd single-point it on the lathe but small stuff just shrinks away from the threading tool and I don't have a steady for the lathe to keep it properly in its place. Die threading is faster if ya got the correct die size, too.

View attachment 337607 View attachment 337606

Honestly, I rarely thread small round stock (more tapping than threading, ya know?) so it wasn't a big deal until now.

So, back to the mall of the Internet for a suitable tool.

Found this 'Floating Lathe Tailstock Die Holder' set from an eBay seller in India. Yeah, I'd be a bit nervous about India too - but more later.

View attachment 337605 View attachment 337604

Kinda like the floating tap holders for the mill, but die holders for a lathe. Ordered one to fit my MT4 tailstock and got all the sizes of die holders in case I ever acquired other dies.

So, I popped it onto the lathe, chucked up (yeah, should use a collet for such small stuff - lazy day, you know?) and tried to make a thread.

First off, my lathe's slowest speed was a bit too fast for my taste in threading - so the next project will be wiring up a variable speed to the VFD - but not germane to today's discussion. So for today I used the clutch to keep the speed comfortable.

View attachment 337603 View attachment 337602

Worked like a charm, actually! Good alignment between the die and the workpiece, and after starting the die down the material it produced a very nice and well-aligned thread. Definitely worth the $70 cost of the tool. Workmanship seems very good ~ No complaints. I buggered the starting threads a bit but that was cockpit error on a first try.

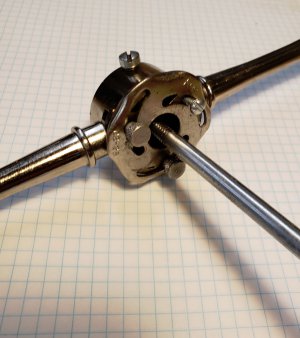

View attachment 337601

The only modification I made was replacing the die holder setscrew with a cap screw so I could change dies without a tool.

View attachment 337600

If you decide to get one of these, shop around. I looked at the same seller's (micromechanics) 'other items' and the exact same tool set varied in price from about $70 to about $140. Very strange I really can't comment on the accuracy or concentricity of the Morse adapter since the business end 'floats' the die on the stock and alignment is meaningless unless it's out by an 1/16th" or so. Cheaper if you buy only the one die diameter you really need, but what's the fun in that? Shipping from India only took 10 days.

Useful tool if you don't already have one.

YMMV and all that, not affiliated with the seller, just a happy buyer.

Stu

Continuing the saga of restoring the GMC motorhome I now needed to extend the valve shafts for the sewer and gray water tanks.

They're threaded 1/4-20 I've used the Ace die stock with the 'pseudo guides' many times, and often get the die stock mis-aligned with the round stock I'm threading, thereby cutting a progressively worse alignment as the thread progresses. If it was larger stock I'd single-point it on the lathe but small stuff just shrinks away from the threading tool and I don't have a steady for the lathe to keep it properly in its place. Die threading is faster if ya got the correct die size, too.

View attachment 337607 View attachment 337606

Honestly, I rarely thread small round stock (more tapping than threading, ya know?) so it wasn't a big deal until now.

So, back to the mall of the Internet for a suitable tool.

Found this 'Floating Lathe Tailstock Die Holder' set from an eBay seller in India. Yeah, I'd be a bit nervous about India too - but more later.

View attachment 337605 View attachment 337604

Kinda like the floating tap holders for the mill, but die holders for a lathe. Ordered one to fit my MT4 tailstock and got all the sizes of die holders in case I ever acquired other dies.

So, I popped it onto the lathe, chucked up (yeah, should use a collet for such small stuff - lazy day, you know?) and tried to make a thread.

First off, my lathe's slowest speed was a bit too fast for my taste in threading - so the next project will be wiring up a variable speed to the VFD - but not germane to today's discussion. So for today I used the clutch to keep the speed comfortable.

View attachment 337603 View attachment 337602

Worked like a charm, actually! Good alignment between the die and the workpiece, and after starting the die down the material it produced a very nice and well-aligned thread. Definitely worth the $70 cost of the tool. Workmanship seems very good ~ No complaints. I buggered the starting threads a bit but that was cockpit error on a first try.

View attachment 337601

The only modification I made was replacing the die holder setscrew with a cap screw so I could change dies without a tool.

View attachment 337600

If you decide to get one of these, shop around. I looked at the same seller's (micromechanics) 'other items' and the exact same tool set varied in price from about $70 to about $140. Very strange I really can't comment on the accuracy or concentricity of the Morse adapter since the business end 'floats' the die on the stock and alignment is meaningless unless it's out by an 1/16th" or so. Cheaper if you buy only the one die diameter you really need, but what's the fun in that? Shipping from India only took 10 days.

Useful tool if you don't already have one.

YMMV and all that, not affiliated with the seller, just a happy buyer.

Stu

Bought myself some well-aged slabs of cast iron! They were apparently used in some factory back in the 50's for adjusting different parts that tended to go out of flat.

The thin slab at 400x800x110mm weighs around 170kg according to the seller, the entire car sagged down quite a bit when we loaded both in ...

Hoping to make a really sturdy table out of these two.

View attachment 337708