-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New PM 932M-PDF arrival

- Thread starter yota

- Start date

- Joined

- Jul 2, 2014

- Messages

- 7,594

Those import machines are quite a bit cheaper to buy than anything currently made in the USA, and they also need to be shipped here. Part of the savings and success of Chinese machines is in not spending additional time and effort in making them pretty. I have mostly old USA machines that are full of dings and chips have some rust, and don't worry about it much. I use them to make things, and the results of that work is how I rank my machines, not how pretty they are. I actually like the patina on old and heavily used machines, they have been doing what they were intended to do for all those decades. This is not a white collar hobby, IMHO...

Those import machines are quite a bit cheaper to buy than anything currently made in the USA, and they also need to be shipped here. Part of the savings and success of Chinese machines is in not spending additional time and effort in making them pretty. I have mostly old USA machines that are full of dings and chips have some rust, and don't worry about it much. I use them to make things, and the results of that work is how I rank my machines, not how pretty they are. I actually like the patina on old and heavily used machines, they have been doing what they were intended to do for all those decades. This is not a white collar hobby, IMHO...

Exactly. To achieve the price point they do, the extra time to detail and polish the machines simply isn’t available. You could easily increase the cost by 25-50%.

Sent from my iPhone using Tapatalk

I had that same thought.Sad that the instructions include directions for cleaning up "machining residue" on a new machine.

the instruction is for cleaning out the inside of the support column, not part of wiping down the shipping grease. makes me wonder what the inside of the gearbox looks like.These machines spend weeks on a cargo ship and then days on multiple trucks. They need to be protected from rust during transit. So, cleaning them up on arrival is needed. Mine just had the protective grease to clean off.

It would be nice if all signs of machining residue were already clean, but why do something that would increase the price if it is going to need cleaning upon arrival anyway?

Sent from my iPhone using Tapatalk

Last edited:

not from the trucking company at all. all these dings where there when this was put in the crate.CONGRATULATIONS!

A few dings here and there from the trucking company no doubt, but I'm sure you'll get that all sorted.

Have fun!

agree but those old machines earned their wounds. if you buy something brand new YOU as the new owner should get to inflict the damage. LOL.Those import machines are quite a bit cheaper to buy than anything currently made in the USA, and they also need to be shipped here. Part of the savings and success of Chinese machines is in not spending additional time and effort in making them pretty. I have mostly old USA machines that are full of dings and chips have some rust, and don't worry about it much. I use them to make things, and the results of that work is how I rank my machines, not how pretty they are. I actually like the patina on old and heavily used machines, they have been doing what they were intended to do for all those decades. This is not a white collar hobby, IMHO...

like I said above, if its accurate and dependable I'm happy.

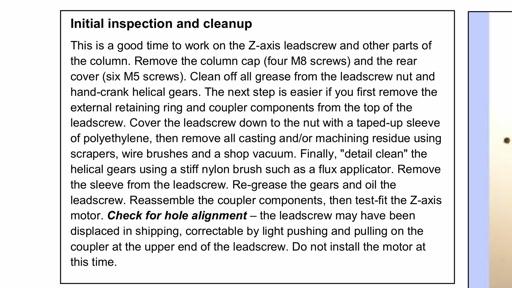

George, you saved me a lot of trouble. I would have gotten to this step but the machine would have been on the stand by then and 15 inches from the wall. your post got me to go thru this work early this morning BEFORE I set the mill on the stand. thank you.Glad you got it In good condition. Page 33 talks about checking the z-axis alignment. Yours may have shifted durin shipment

Sent from my iPhone using Tapatalk

better pic of the top of the lead screw. there is no way I could see that the leadscrew could be dislocated in shipping. when I took the access plate off the back of the column the lead screw looks cocked. the only way to adjust this would be to shim out the thick cast plate at the hand crank to pull the bottom over. if I did this then the 4 screw holes they drilled and tapped in the top plate would no longer align with the Z axis lift motor base holes. going to live with it.