unboxed parts that were made before the mill or bigger lathe arrived,, just do with the little unimat SL1000,, did some test fitting and mounting,, plus milled up a few more parts,, did some mocking-up to make sure there will be spaces for the fuel tank or tanks,,

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1/6th scale 1890's 30ft navy steam cutter (live steam)

- Thread starter tghsmith

- Start date

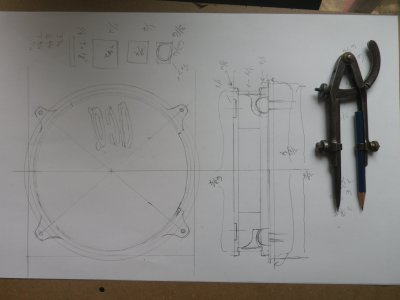

some kind of not perfect cutting methods this morning, but I got away with it ,, working on the boiler base unit, its will be three brass rings, with a formed (rolled) sheet brass section to get the height,, modded a drill press circle cutting tool to do the cores, once the cutter was ground a bit it worked fine,, cut the disc from each side,, lots of clamps and safety gear,, used a big bandsaw to knock of the corners,, all are just a hair big for the lathe so the rotary table will get set up on my mill,, lots of cranking that little handle..

Attachments

set up the mill with the rotary table and started making lots of swarf!!! two rings done and formed the strip stock with the rollers and percussive adjustments.. some trimming of the strips to fit and it will get soldered up..

Attachments

they are better than that,, great things to have if you silver solder stuff

www.riogrande.com

www.riogrande.com

Knew Concepts Titanium Soldering Strips, Set of 10 - RioGrande

pesky complex small but had to make parts "boiler feet" milled the foot section, formed parts were silver soldered in place, back on the mill with a spacer to cut the steps, then cut the milled apart for the feet.. they will get soldered and riveted onto the base once it is all soldered..