- Joined

- Feb 25, 2021

- Messages

- 3,129

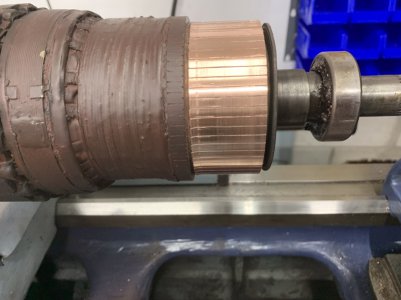

Here's what it looks like so far. Quick change gear box (QCGB) rehung, most of the covers in place, even if covering empty space. Second picture is the bench of parts left to go. At least that is most of them, there are a few more in various corners of the garage, and the motor and electronics on the electronics bench, etc.