Are you SURE that you didn't accidentally pick up a piece of balsa wood that was painted black for another project? LOL

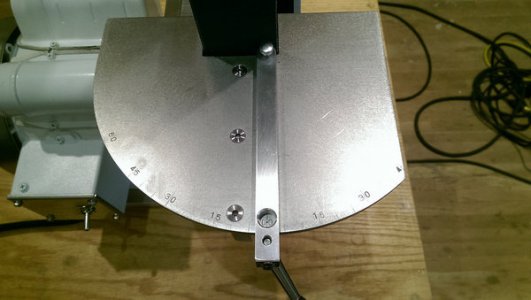

Nice sander/grinder that you built, works well and looks good. Very professionally built.

Have you figured out how many actual dollars you have invested?

Nice sander/grinder that you built, works well and looks good. Very professionally built.

Have you figured out how many actual dollars you have invested?