-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2013 POTD Thread Archive

- Thread starter HMF

- Start date

- Joined

- Apr 12, 2011

- Messages

- 3,483

The reverse counterbore tool came from Brown Aviation today.

Walt

Hey Walt, thanks for the lead, I just bought their 14 piece kit. What a great idea.

Kit

Last edited:

- Joined

- Jun 22, 2012

- Messages

- 1,552

Today's task was to move some stuff around in my shop to make room for the burke mill. I am kinda dedicating one corner of my wood shop to the metal machines, I will cover them when I am doing wood working.

Here you can see the south bend in it's place, a free aluminum back splash mounted on the wall, and to the lower left of the wall cabinet a plate mounted to the wall where the vfd will go.

This is all the stuff I had to move to make room for the mill'

All ready for the mill. I think I can leave the shelf on the wall.....we'll see.

I really need to move and get a larger free standing shop, half metal and mechanical shop and half wood shop.

Here you can see the south bend in it's place, a free aluminum back splash mounted on the wall, and to the lower left of the wall cabinet a plate mounted to the wall where the vfd will go.

This is all the stuff I had to move to make room for the mill'

All ready for the mill. I think I can leave the shelf on the wall.....we'll see.

I really need to move and get a larger free standing shop, half metal and mechanical shop and half wood shop.

- Joined

- Dec 25, 2012

- Messages

- 184

The reverse counterbore tool came from Brown Aviation today.

Walt

At work, we refer to that style as Back Spot Facers

( Just some other key words to use for searching )

Today I wired an outlet (220/15), made an ext cord, and powered up my new 2me 12x36 lathe. It is in extremely good shape. The previous owner used only very ocasionaly to work on pool ques (!?!). The 4 jaw chuck is still in its little shipping crate! I'm cleaning her up, there is still the wax/grease from shipping in a lot of places.

- Joined

- Apr 2, 2013

- Messages

- 230

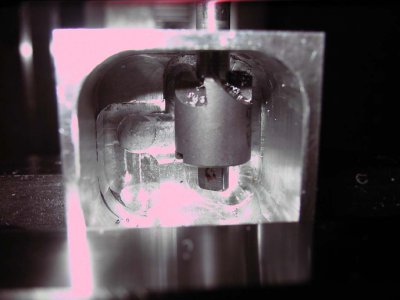

Today I decided to make my spindle box and see how good I could get it (or how badly is screw it up). Cut my bits and bored the ends for the spindle bearings. Welded a stop plate on the back side of the holes for a bearing race stop (as the bearings are almost 3/4" wide and that's what I used for the ends, which made boring easier).

Used a ground 90 angle I had and clamped everything up tight, and then welded one end to the back plate

Welded the two sides on, then test fit the other end. Looks good, so I welded up the other end. Did all the welds inside just to hold it, and just in case I mess up I can separate them. Shaft moved smooth. Did a proper deep penetrating weld on the outside seams and then decided to check how goo I got this. Using my gauge I got an off round deviation of 0.0005 (smallest increment the gauge will show) ... almost peed myself I was so happy.

Decided to kieep going (even though my back was screaming NOOOO) and ground off all the welds to make it nicer looking and to check the weld penitration. Once done I was whacked, so I painted the thing with my standard tremclad grey and called it a day ..... Still smiling, soon the lathe will be done ... again.

Used a ground 90 angle I had and clamped everything up tight, and then welded one end to the back plate

Welded the two sides on, then test fit the other end. Looks good, so I welded up the other end. Did all the welds inside just to hold it, and just in case I mess up I can separate them. Shaft moved smooth. Did a proper deep penetrating weld on the outside seams and then decided to check how goo I got this. Using my gauge I got an off round deviation of 0.0005 (smallest increment the gauge will show) ... almost peed myself I was so happy.

Decided to kieep going (even though my back was screaming NOOOO) and ground off all the welds to make it nicer looking and to check the weld penitration. Once done I was whacked, so I painted the thing with my standard tremclad grey and called it a day ..... Still smiling, soon the lathe will be done ... again.

- Joined

- Mar 10, 2012

- Messages

- 1,368

Today's task was to move some stuff around in my shop to make room for the burke mill. I am kinda dedicating one corner of my wood shop to the metal machines, I will cover them when I am doing wood working.

Here you can see the south bend in it's place, a free aluminum back splash mounted on the wall, and to the lower left of the wall cabinet a plate mounted to the wall where the vfd will go.

View attachment 51338

This is all the stuff I had to move to make room for the mill'

View attachment 51339

All ready for the mill. I think I can leave the shelf on the wall.....we'll see.

View attachment 51340

I really need to move and get a larger free standing shop, half metal and mechanical shop and half wood shop.

I was wondering why you weren't posting about making chips fly on the Heavy 10 yet! That's a nice shop. Too clean!

- Joined

- Jun 22, 2012

- Messages

- 1,552

I was wondering why you weren't posting about making chips fly on the Heavy 10 yet! That's a nice shop. Too clean!Is that a VFD for the lathe I see on the cart?

Too clean.....HA HA, Now that's a good one, I will get a pick of the other side and you will see that I'm human and a.d.d. to boot! And yes that is the vfd for the lathe.

But on another note, the burke is in it's place today, pics to follow. I oiled everything up and turned all the handles to distribute the oil, oiled all the ways and machined surfaces. Wired the motor back up and threw the switch.........it's amazing how smooth a 70 year old machine can be, pretty quiet too! When the motor runs you get a smell like running old lionell trains, you know that old oil and electricity smell, very cool to me.

- Joined

- Dec 22, 2011

- Messages

- 715

When the motor runs you get a smell like running old lionell trains, you know that old oil and electricity smell, very cool to me.

Wow, I haven't smelled that for well over fifty years but it came flooding back as soon as I read that. That is a distinctive smell.

Steve

- Joined

- Nov 16, 2012

- Messages

- 5,596

I still have an original Lionel set (with original boxes) from the late 40's and whenever I open the box to check it out, it still smells the same. I think it's from the little smoke pills that cooked from a heating coil inside the smokestack.

Ray

Ray

Wow, I haven't smelled that for well over fifty years but it came flooding back as soon as I read that. That is a distinctive smell.

Steve