- Joined

- Nov 21, 2010

- Messages

- 1,602

There was a thread earlier this month regarding a shear cutter for shapers, seams to have disappeared or I can't find it.

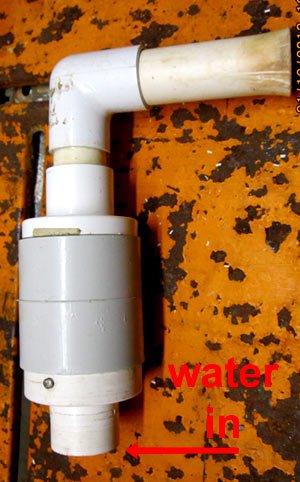

In the thread I'd asked for tips on how to reduce chatter while I was cutting teeth on a rack. One of the suggestions was to eliminate the tool holder and mount a larger blank directly on the clapper.

Tried it today and can't believe the difference.

Who ever it was that suggested it THANKS.

View attachment 65210

Greg

I dont know if it was me or not, cause I dont use a holder either.

Nice job yer doing

sam