- Joined

- Jun 15, 2013

- Messages

- 1,199

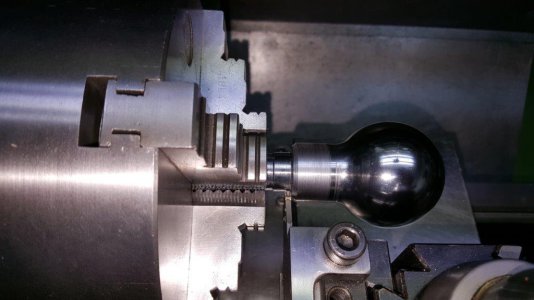

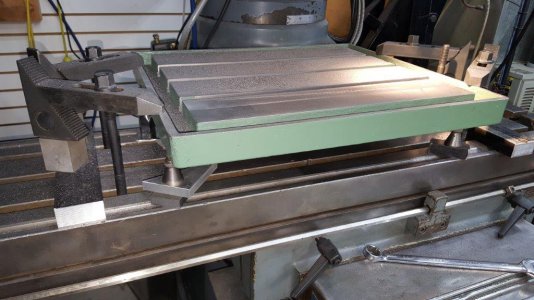

I made a couple indexing holders, one specifically to hold new iscar pqlnr tool, which uses qnmg inserts, I got the holder on the cheap, it started as a 1 inch, but soon became a 3/4 shank, the qnmg is a negative insert, the holder lays down a little, but the TF geometry is described as very positive rake with low tool pressure, I'm using it on my atlas, and am extremely pleased with the surface finishes I get with it, taking .080 cuts is cake in 4140, but even in cr1018 the surface was quite impressive. The oversize holders I made for the tool post we're dimensioned slightly off dorians size 30 indexing holders, I don't have an indexing post but, they look cool haha, the inserts are big, 431 size, it's all big boy tools, the finish on the tool holder looks really cool, almost scraped looking, was hard to get same shot of that, only part I didn't make was the nut and set screws, I did the knurling and threaded rod, learned something about my knurling tool, I ran it at 400rpm, and traversed it off the work, stopped and traversed back towards the headstock, perfect knurl, mind you I had already made 3 passes and it looked like crappie until I walked it off the work and back on