- Joined

- Aug 19, 2013

- Messages

- 764

I like the project. How did you get the split ring open wide enough? Those rings can be a bear.

Try an office staple remover.

I like the project. How did you get the split ring open wide enough? Those rings can be a bear.

Here's a photo of the workbench prior to disassembly for paint.

Thanks for the encouraging words gentleman. I was too tired to post yesterdays progress. I moved in the WB and located, leveled and started loading toolboxes,plywood steel top and tools. Today will be more of the same cleaning tools prior to loading.

I need some ideas on toolbox organizers from you all, so please share what you use to keep the tools in their place. I will not use foam shadow as this is not practical for me.

Thanks in advance for your input.

I need some ideas on toolbox organizers from you all, so please share what you use to keep the tools in their place. I will not use foam shadow as this is not practical for me.

Thanks in advance for your input.

Yesterday wasn't much of a shop day. We had a cookout with our daughter, son-in-law, and grand kids.

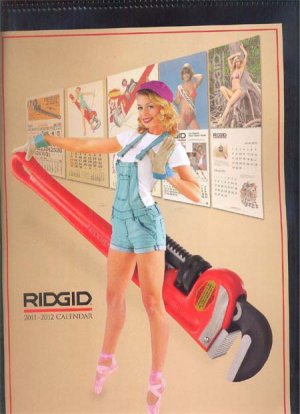

I did show the son-in-law that I had gotten my Garvin horizontal mill running. Looking around my tiny shop he made some joking reference to decor. Now my shop is very small and barely fits my machines, tool boxes, etc. The only thought I had given to decor was when I rejected the clock that the wife offered to give me and bought a more institutional looking one. But when I heard his remark it came to me. I knew the thing my shop was missing:

A pinup girl tool calendar!

Later I went on ebay and ordered this one:

View attachment 110110

I know that it's out of date, but I'm retired so it really doesn't matter. Besides, it's from the year I retired.

And in the words of John Keats, "A thing of beauty is a joy forever."

I need some ideas on toolbox organizers from you all, so please share what you use to keep the tools in their place. I will not use foam shadow as this is not practical for me.

Thanks in advance for your input.

Thanks for the encouraging words gentleman. I was too tired to post yesterdays progress. I moved in the WB and located, leveled and started loading toolboxes,plywood steel top and tools. Today will be more of the same cleaning tools prior to loading.

I need some ideas on toolbox organizers from you all, so please share what you use to keep the tools in their place. I will not use foam shadow as this is not practical for me.

Thanks in advance for your input.