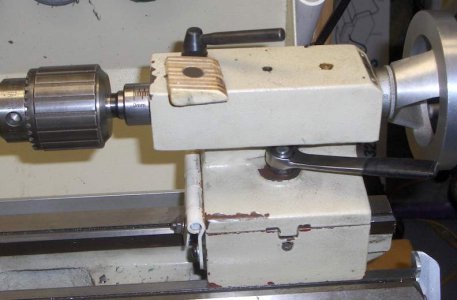

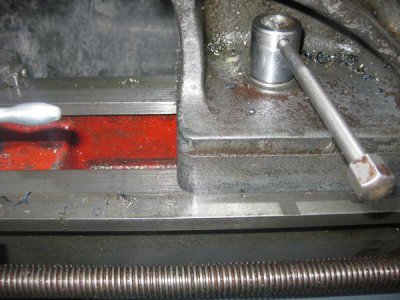

Today, I fixed the hand-piece on our kitchen sink with my lathe. There was an inner rubber tube and a flexible outer metal jacket that connected between under the sink and the hand-piece. The flexible metal jacket broke off where it met the hand-piece which then weakened the inner rubber tube, and that burst... so I had to remove the bad parts and in doing so, I destroyed another piece inside ("good luck finding that replacement part", I thought)... so, I decided to turn a new coupler out of a piece of 2011. Sadly, I didn't think to take pictures of it, but it worked better than I had hoped! Of course I had to yell "Booya!"