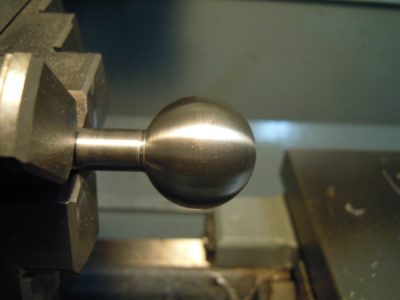

I like having feedback, especially about machining, carpentry I pretty much have figured out

View attachment 244388

View attachment 244388

That is the exterior, tyvek the top 5 foot, 30 lbs felt paper tucked in under, taped for the bottom 3 foot, than 7/16" durock screwed on. Stone and siding being ordered tomorrow.

View attachment 244389

Water board drywall going on all wall, this part of the shop was very dark, just having the drywall on the walls makes this part of the shop much brighter now.

View attachment 244390

I'm not sure that helps anyone else, it's been a fun project, I can't wait to get all the construction done so I can start playing with machines again...

Sorry to anyone offended , stubborn old men...