- Joined

- Dec 27, 2017

- Messages

- 340

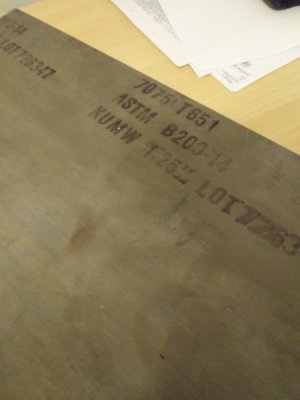

I don't think this one has a way to offset the measurement from inside to outside. It does have a laser etched spot that says 0.8" on the jaws. So I guess they figure I can just add .800 to whatever my internal measurements are.I have a 24 inch dial calliper, it gets used fairly often. On the digital, how do you switch from inside to outside jaws? On my dial one there are two scales on the beam, reading the wrong one caught me a couple of times.

Greg

. I have used a BP 6" since I got into the hobby machining about three years ago, so this is a real treat for me

. I have used a BP 6" since I got into the hobby machining about three years ago, so this is a real treat for me