F

Firestopper

Forum Guest

Register Today

If you want the cutting edge to stay sharp for long production runs you probably should harden.

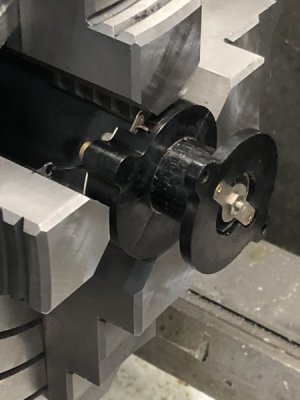

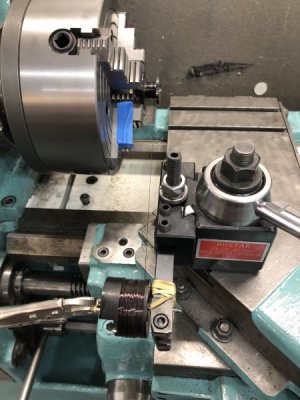

I bought a Williams T 1 S tool holder. Payed $9.00. So not a big investment. It accepts 5/16 tool bits. I milled it down in the lathe. mounted it in a tool holder horizontal. Then did the cutting with a 3/4 end mill held in a 5c collet. This is Abomb79 style. He deserves all the credit. I wanted to be able to take advantage of the smaller tool steel. I’m happy with the results.

View attachment 272606

Did you do this because you don't have a tool holder for 5/16?

The 5/16 tool bits are kinda to small for the bxa tool holders. You can shim them up. The problem is there short and you don't get much stick out if you want to catch 2 of the set screws in the tool block. This set up is rigid with good projection. Plus I can hold short tool bits. I could actually cut a tool bit in half and still hold it safely.

Hope this makes sense.

Not exactly in the shop, but a project nonetheless.

About 2 weeks ago the dogs started tracking mud into the kitchen from outside.But I hasn't rained here in about a month, there is no standing water anywhere. They like to dig a hole and lay in it when it gets hot so I just assumed it was coming from that, but I couldn't find any mud, just some dry dirt. Well it turns out I was wrong. I followed one of them out by the the fence and found the mud.

It turns out that the well water line was leaking at the wellhead, about a gallon a minute.Wasn't enough to really cause a water pressure drop so didn't affect anything in the house so I didn't know I had a problem. So grab a shovel and start digging around the well casing, I can see where the water is coming up at so dig in that area.....Until I hit a big tree root.

Then the fun begins. Ok, dig around the root, carefully, so not to hit the electrical cable or actually break the pipe. Finally was able to get air under both ends of the root and no pipe or cable in the way, so grab the chain saw and cut the root at both ends, about 4 inch diameter. It was pretty much welded to the pipe, had to make another cut to get it loose. Also pretty much destroyed the saw chain, they don't like mud.

All this time the water is still leaking into the hole, but I was able to dig a channel to keep the work area dewatered. I didn't turn the well pump off because I didn't want groundwater leaking into the well so I was keeping the system pressurized.

Ok getting closer to the leak, so dig a bit more and.......Hit another big root. So start digging around that root and now I'm deep enough that my drainage channel is no longer working and I'm below the lawn grade so I can't go down any more. So off to the rental shop and rent a trash pump. Dug a sump for the pump pickup and keep digging.

This time I found the electrical cable and the water pipe, kind of under the root. Clean out under the root and grab the chainsaw again, got that root out by cutting it into 3 pieces. So now I have about a foot of the water pipe exposed and know exactly where the power wire runs. But......

The water pipe connection to the Pitless Adapter is back under another even larger root, about an 8 inch or so. By this time I'm into this about 1 1/2 days. Now it was time to turn off the pump, cut and cap the water pipe on both sides of the cut to keep the mud out. So dig out around the pipe and remove a couple of small finger roots that were intertwined with the power cable. So after more digging to get some working room I was able to cut and cap the water pipe.

Now time to attack the big root, and the one that started the whole problem. Tried getting through it with the chainsaw but the chain was so dull by now it was useless. So grab the Sawzall and start removing pieces of root. About 2 hours later, I can finally get to the broken fitting.

I didn't get any pictures of the process, but I did take a few after the repairs were made.

The view from outside of the work area.

View attachment 272393

That's a lot of dirt, you get down about 8 inches and it's gooey clay, nasty stuff to dig in. A few pieces of root laying around

View attachment 272394

And the repair, a piece of schedule 80 screwed into the Pitless Adapter, and schedule 40 for the rest. It's about 3 feet down to the pipe. The other piece of pipe that is capped off was abandoned when the pump was replaced in 1989, I have no idea where it goes. The root system all grew in the last 29 years. I may dig out that big root laying on top of the pipe, it's not connected to the tree any longer.

View attachment 272395

For those of you who do not know what a Pitless Adapter is

View attachment 272398

The white blob just to the left of the well casing was the big root that actually broke the fitting.

View attachment 272397

That tree was probably a lot smaller 29 years ago. I have no idea when the well was dug, but I'm guessing that tree was about Christmas tree size when the well was installed, it's about 100 feet tall now, and maybe it was planted after the well was in. Not the best place for a tree that will develop a large root system. The good news is that there are a lot more big roots holding the tree up, so even with what I took out I'm pretty sure it won't fall over in the next wind storm.

View attachment 272396

I suspect this has been leaking for a year or more and just getting worse over time. It just finally surfaced in the last couple of weeks. I'll be filling in the hole with pea gravel, not going to fight that clay again if I ever have to go back into that hole. I'm getting too old for this, that was a lot of work.

The 5/16 tool bits are kinda to small for the bxa tool holders. You can shim them up. The problem is there short and you don't get much stick out if you want to catch 2 of the set screws in the tool block. This set up is rigid with good projection. Plus I can hold short tool bits. I could actually cut a tool bit in half and still hold it safely.

Hope this makes sense.

Well you did get the Williams cheep enough. I’d probably mill a piece of square stock to fit the block and the tool steel

Sent from my iPhone using Tapatalk

That is awesome Bruce. You're going to enjoy that.Didn't make it in one day, probably around 30 hours time. Put in a set of shelves in my shop 8' x 6' tall x 2' deep about 15 years ago. They were organized at the time . . . Boxes of screws, nails, bolts, cans of stain, air nailers, etc., etc, etc. have been shoved on the shelves over the years. I invested in a few Rubbermaid tubs to throw in like hardware like electrical, cabinet and plumbing stuff. So need an electrical switch, pull out the tub and dig through it to get what's needed.

Plan is to replace the storage rack with a pair of 4' tall x 4' wide x 2' deep drawer units. Made the cabinet out of 3/4" plywood, drawers out of 1/2" ply. Had our 22-year old son in the shop to help with the cabinet making. Gave me a chance to pass along some tips/tricks I've learned over the years like how to cut a dado in the dead center of the top/bottom so it's perfectly centered so drawers are interchangeable side to side. I use a 1/2" dado blade and cut the dado close to center, then flip the board and make a second pass running the opposite side against the fence. Then measure the width of the dado relative to the width of the divider board and move the fence away from the blade a little less than half the difference. Keep making passes with opposite sides of the top/bottom against the fence with little taps on the fence until the divider just slides in (sand a little taper on the sides of the divider at the top and bottom).

Anyway, made good use of the dovetail router fixture fixed above. Drawers are 3", 4", 3 6", 8" and 10". They're mounted on full-extension glides rated at 100 lbs., so doubled them up on the 8" and 10" drawers just in case. The glides are pretty cheap nowadays. Got 30 sets of 22" full extension glides off eBay for $135 including shipping. I remember these being something like $15 each back in the day. Brushed on 3 coat of polyurethane for a finish, no stain. I set the drawers back in the cabinet enough to put doors on, but will probably leave them as is. The spacing is 3/16" between drawers which is hopefully a little too small for mice to squeeze into!

Next step is emptying the rack and getting it out of the way for the first of the two cabinets. I'll start filling drawers and will make the second one based on what's left to store. Would hate to make a couple of banks of 6" drawers and find out I need 7" deep ones.

Thanks for looking!

Bruce

View attachment 272040

View attachment 272041

View attachment 272042

View attachment 272043

View attachment 272044