Another little clean-up project that has been sitting on my books for a long time. I hate to admit it, but I started this one all of fifteen years ago. Then parents started dying and estates needed to be settled, so here I am finally getting around to putting the thing back together.

It's a forge blower in case you haven't figured that out yet. Made by Canedy Otto, a "Royal" Western Chief from around the turn of the century (I think). No stand with it, and when I bought it there was some damage to a few of the screw bosses as well as a particularly offensive green and black colour scheme. The crank handle was also reduced to a stub and missing the ball counterweight. But aside from that, it seemed to work okay.

When I tore it all down the insides looked really good. Hardly any wear on the gears or shafts. And there was my first surprise: one of the gears was not metal. It's like a hard rubber, and after a bunch of head scratching I determined that this was what Canedy Otto called their "whisper quiet" gear train or something like that. Basically one synthetic gear intermixed with the regular gears to make a quieter running train. I can't put my hands on the ad where they talked about it, but I may still have it in a file somewhere. That's what happens when stuff drags out for so long.

View attachment 288060

View attachment 288061

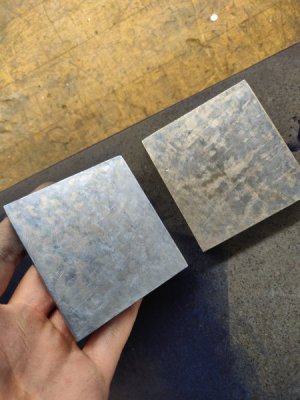

My second surprise was the paint colour. I knew the green was wrong from the get go, but I wasn't prepared for the traces of burgundy with gold letter highlights that I found underneath it. But I guess if you were offering a model called "Royal" that'd be one way to make it distinctive. They picked out the fan, visible only through the side intake hole, in red.

Here's some of the body castings getting the new burgundy colour. There was enough original left for me to get a pretty good match, and even though in this picture it looks a little bright the colour will darken in as it dries.

View attachment 288062

View attachment 288063

The fan needed a bit of balancing I guess, so there's a small tab of lead riveted on to the end of one of the blades. You can barely make out faint remnants of the red paint around the rivet heads.

View attachment 288064

I happened to have this brass stopcock in my drawer of salvaged bits. It's not far off the proper vintage and a dead ringer for the oil drain cock that originally came on these blowers. 1/8" national pipe thread, it fits perfectly. For the oil filler cup on the top I ended up turning one up from scratch. Even though I'm not going to be filling the gear case with oil any time soon, I want everything to work like it should for anyone who might have it after me. Still haven't made myself a knurling tool yet so I just cut fine grooves around the top of the cap using the lathe. It goes pretty fast, especially in red brass.

View attachment 288065

View attachment 288066

View attachment 288067

I decided to repair the existing crank handle rather than making a completely new one. The original is cast and has an elliptical cross-section which I figured I could make easily enough on a small length but not so easily on a longer length. I was able to rough out a lot on the shaper, and the rest I took care of by hand.

View attachment 288068

After debating several methods of joining the new piece to the old crank, I opted to make a hollow sleeve to bridge the joined sections. I got a pretty good slip fit, then used JB Weld to hold all three together.

View attachment 288069

View attachment 288070

Turning the ball was a bit of adventure as well, actually that's not true, it was tedious more than anything. I really need to make a ball turning attachment sometime. And for the through-hole, lots and lots of filing.

View attachment 288071

View attachment 288072

And that's pretty much all she wrote. I turned a new handle from a scrap of black walnut I had lying around, put it all together onto a stand, and set it in my living room for now. I'll sell it one day, or give it to some deserving party when the time is right. The odds of me running a coal fire again where I live are pretty slim, and I have a new propane forge that I've never even fired up yet. So for the moment the Royal Western Chief is purely eye candy, but it's still better than TV!

View attachment 288073

View attachment 288074

View attachment 288075

View attachment 288076

As always, thanks for looking!

-frank