Continued on with my project from

https://www.hobby-machinist.com/thr...you-make-in-your-shop-today.67833/post-647558

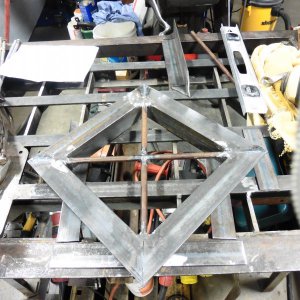

Made the mount for the jackshaft that reduces the speed of the engine to drive the broom attachment so it mounts behind the engine, so the belt to the broom is long enough to have the twist in it needed to run the brush in the correct direction.

Hopefully this is rigid enough for the pulleys, as both belts will be pulling it forward, and the bottom one has a very strong idler spring on it, but it should be ok. The bar the pulley is mounted to is 2x3/8", and the primary pieces preventing that from twisting are the 2 2x1x1/8" rectangular tubes, notched and welded all around the bar.

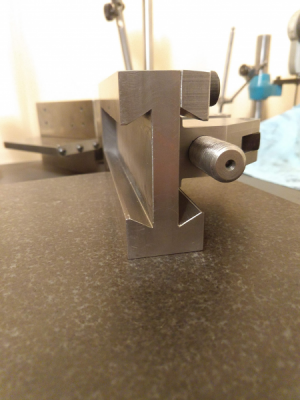

I almost nailed the top pulleys location right off the bat using measurements, but once it was welded together and installed, the top pulley was 1/8" out of alignment with the pulley on the engine, so I made a spacer to drop it down to get it right in alignment. Once I get a belt for it, I can figure out how/where to mount the spring for the idler to keep the belt under proper tension.

And while I was under there, I noticed the belt driving the wheel hydraulic system was missing chunks, so I'll get a replacement for that as well.

So, tomorrow, some shopping for belts and nuts/bolts for this mount, then I spend some time figuring out how long the belt to the brush should be. It's a bit more difficult to figure out, as it has to support lifting the broom as well