- Joined

- Nov 19, 2014

- Messages

- 991

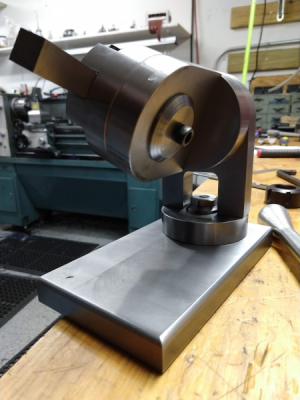

The season of turning, drilling, and milling is slowly giving way to the season of mowing, tilling, and grilling; here's one last project until I pick my pumpkins. I built my chassis jig in 1996, and have never liked the bracket we use to handle rear ends. As you can see the present version has been modified a number of times, it's OK, but I can do better. If it's in the way on top of the jig, then I'll suspend it from the bottom of the jig, first I need to build a pair of beam clamps. Here's how I cut the 8 degree angle to match the flange on the beam, I keep a lot of small pieces of steel around just for clamping, setting up ect. I bought this tapping fixture from ENCO when they were less than $80.00, it sure is handy when you've got a lot of holes. Here's one of the clamps with the hanger attached, my 2" x 2" square tubing parallels will slip through the 2 1/2" X 2 1/2" X 1/4" square tubing after a little massaging with a die grinder. Here's the clamp assembly and parallel fit up to the Jig. Here's a close up of the slider, it has a 1/2 " locking bolt on the bottom and supports the 1" adjustment screw, topped off with a peace of 1 1/4" X .120" tubing and a yoke made of 3"pipe. Last but not least, the retired race car that has been storing the rear end for the last 20 years.