Not machine related, and pretty much wore me out. Finished cutting my firewood today. 24 inch blocks of oak get real heavy at the end of the day.

View attachment 295548

Greg

Hi Greg,

I feel your pain . . . Ibuprofen helps, 800 mg is a prescription dose or 4 over the counter 200 mg pills, ask me how I know . . . To me, the worst part of heating with wood is the task is never done. Get all of your wood cut for the year, and you get to do it all over again next year.

I finished up today with "Woodstock 2019", got the last of mine cut, split and stacked for this upcoming winter. We burn between 7-9 full cords a year (9+ this year . . .). I'd like to think I've gotten a little smarter over the years (been supplementing our propane heat with wood since 1991), do the same amount of work each year, but spread it out much more that 60 is just around the corner.

Michigan got hit with the emerald ash bore a few years ago which pretty much wiped out all of the ash trees. We live on 64-acres with ~50 of it wooded, mainly dead ash, hard maple, walnut, cherry and some elm (lots of dead standing elm).

I hit the woods in September with a satellite map of our property and look for downed trees (do most of my cutting in late fall, early winter). If there are dead standing trees, paint them with fluorescent orange or green paint and mark them on the map. Kinda tough to tell in the winter if a tree is live or dead with no leaves, hence the paint job. I cut with a Stihl Farm Boss, go out with a quad and 3' x 5' trailer and run 2 - 4 tanks of fuel through the saw, then call it quits for the day. Stuff that doesn't need to get split hits the trailer and gets stacked. Yes, I'm anal, I count tanks of fuel through the saw to know when I've cut enough for the next year. Usually takes 26 - 32 tanks of fuel through the Stihl (did 33 this year). I also touch the chain with a diamond bit in a Milwaukee M12 die grinder in the field. Also carry two fresh chains and an extra bar for when (not if) I pinch the bar in a tree).

Already looking forward to "Woodstock 2020" . . .

Bruce

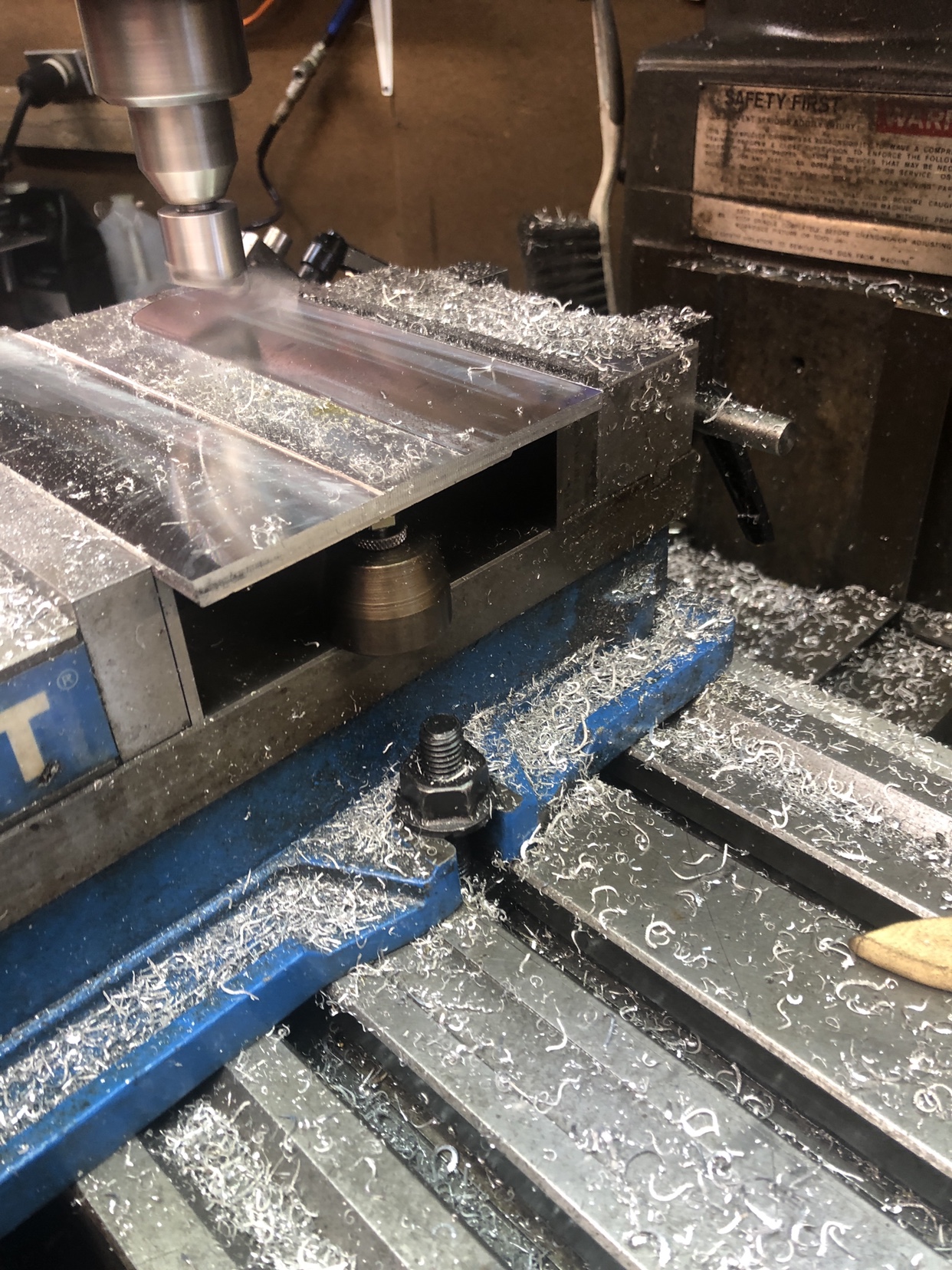

Main storage space in our barn. 40' x 8' high, 2 rows; one additional row 24' x 8' high or a little over 8 full cords. My wood pile as of May 26.

All done (for this year . . .) on May 28.

Walk-out basement area, another 1 1/2 full cords

Garage with another full cord