- Joined

- May 13, 2019

- Messages

- 1,016

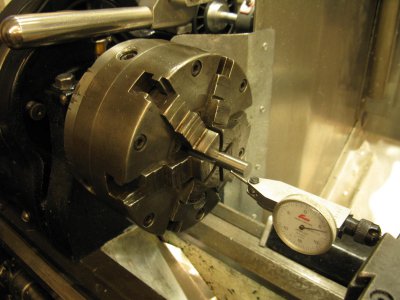

is it sharp? it's hard to tell from the pic. but if you were working with a sharp metal edge all day, you would not like it.

I had a spackling knife like that and when doing my basement, it really left me raw.. so I always think, do I want to handle that all day.

plus, sharp may leave some marks on some stock.

Yeah. I'll soften the edges a bit.