- Joined

- Sep 5, 2013

- Messages

- 3,207

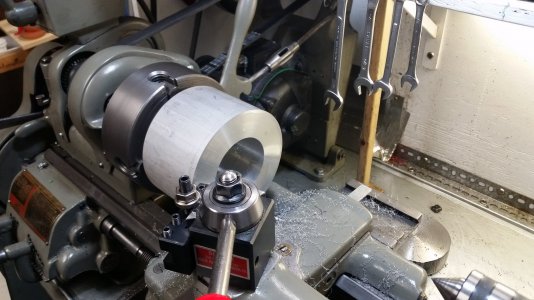

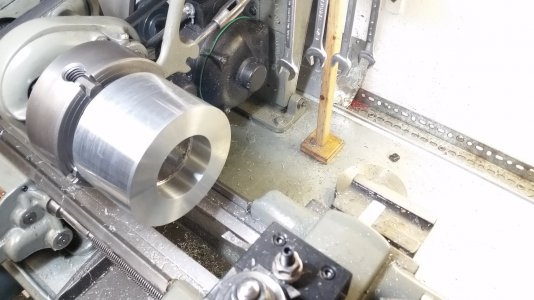

Well it was ugly with much gnashing of teeth, but I got it. The shaft was bent on the hand wheel end (how this could happen I’ll never know) so much so that it could not be withdrawn out the front because of the bend — it wouldn’t pass through the hand wheel bearing anymore. And on the front end was the cast iron counterweight and pitman with the seized set screw that prevented the shaft being taken out the hand wheel end. Ugh, the only access at it was through the little 1/2” diameter hole on the side of the chassis. Decidedly not pretty, but I have a whole new respect for the strength of the aluminum chassis.

Now to see if I can straighten the shaft which is what started this whole ordeal in the first place…

-frank

Now to see if I can straighten the shaft which is what started this whole ordeal in the first place…

-frank