- Joined

- Jul 14, 2017

- Messages

- 2,448

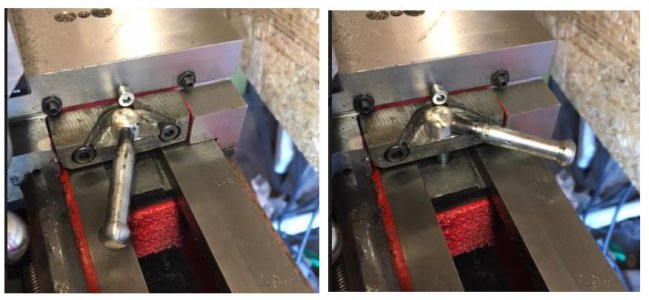

I did a small machining project on my lathe today. The project is to make me an attachment so i can test the cooling system on the 607. I did reuse the radiator cap that i previously used but i enlarge the hole, threaded new threads and machine a new shaft for the air to pass thru. I've been fighting with the plastic cooling system on the 607 for the time i've owned it, and every time i work on it reminds me why i like owning and driving older cars, they used steel, aluminium and brass in there parts.

![20210102_083357[1].jpg 20210102_083357[1].jpg](https://www.hobby-machinist.com/data/attachments/308/308779-f583f44ed36d5f9265f23cf82705c00e.jpg)

![20210102_151538[1].jpg 20210102_151538[1].jpg](https://www.hobby-machinist.com/data/attachments/308/308780-a5f94371fb977df6b713c836c95cec9f.jpg)

![20210117_160727[1].jpg 20210117_160727[1].jpg](https://www.hobby-machinist.com/data/attachments/308/308781-53b5832b1f10b2e8d628e88c51d3f4ee.jpg)

![20210117_125027[1].jpg 20210117_125027[1].jpg](https://www.hobby-machinist.com/data/attachments/308/308783-3f75f700f5d2e0f57a39c6e416925aeb.jpg)