-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2021 POTD Thread Archive

- Thread starter Gaffer

- Start date

- Joined

- Dec 15, 2018

- Messages

- 785

Thanks for sharing Francist. I've never used them either but will have to give it a try some day.

Incredible work as usual.

Working in the cabinet shop the last couple of days with a puppy thinking she's helping. lol

Greg

Incredible work as usual.

Working in the cabinet shop the last couple of days with a puppy thinking she's helping. lol

Greg

- Joined

- May 13, 2019

- Messages

- 1,016

I made a file holder/stand using PVC pipe for the holders and a simple wood base to hold them upright. I stole the idea of using PVC pipe from someone on this forum. I was looking for a simple, fast, cheap solution and this one fit! Literally took 10 minutes to make. The base is high enough to keep the pipes vertical and I can add more in the future, if needed, by expanding the wood base. It takes minimal bench space by keeping them upright.

Attachments

- Joined

- Aug 6, 2015

- Messages

- 3,886

Not a project... a repair... From the lyrics of an Eagle's song...

Take it easy

Take it easy

Don't let the sound of your own wheels

Drive you crazy

I was working the mill too hard and it took out a fuse, the switch, and circuit board (P0704081 - CESX 1101-28)...

Baby is back! Now to finish that anvil...

Take it easy

Take it easy

Don't let the sound of your own wheels

Drive you crazy

I was working the mill too hard and it took out a fuse, the switch, and circuit board (P0704081 - CESX 1101-28)...

Baby is back! Now to finish that anvil...

Last edited:

- Joined

- Jan 20, 2021

- Messages

- 296

This is a stab for circuit breaker testing. Design in Fusion 360. I decided not to machine the holes.

OP1 was on the manual lathe, turning to size, facing and chamfer.

This was my first time drawing, making and using soft jaws on the CNC mill.

They turned out really well. Worked great!

The AB Tools Shear Hog is an incredible roughing tool!

Finished parts.

OP1 was on the manual lathe, turning to size, facing and chamfer.

This was my first time drawing, making and using soft jaws on the CNC mill.

They turned out really well. Worked great!

The AB Tools Shear Hog is an incredible roughing tool!

Finished parts.

- Joined

- Jan 20, 2021

- Messages

- 296

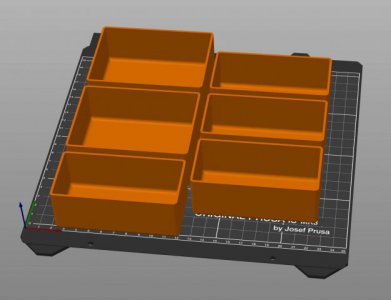

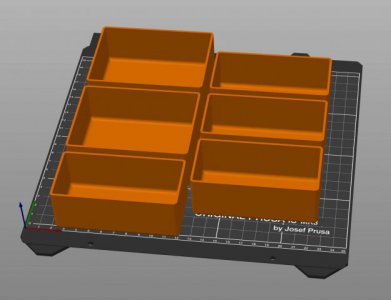

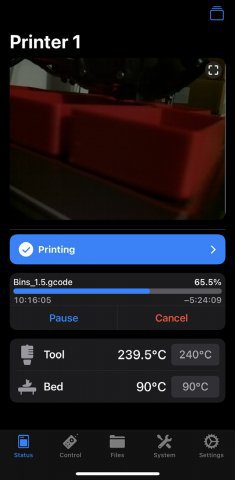

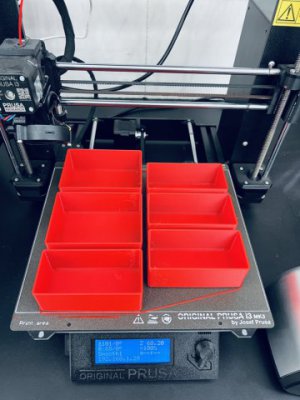

The HF Icon tool chest has very shallow drawers I dare say it’s a huge oversight on their part to make them <2” deep. This means the 2” Schaller bins are too tall. I use these bins all over the shop. So.. 1.5” bins and some PETG it is!

All dimensions in this model are parameters. This makes it trivial to change size. Next was to print it.

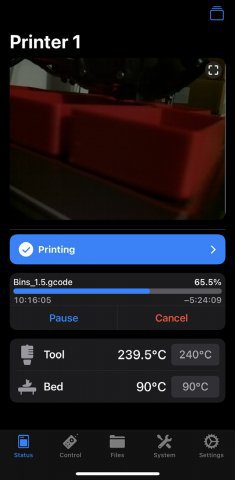

Checked status when I woke up this morning via the OctoPi. Looking good!

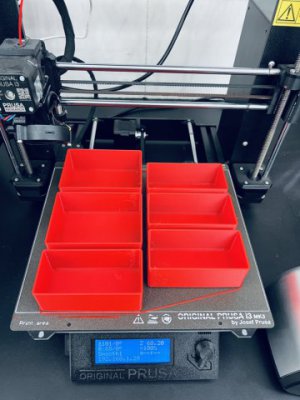

Fresh off the printer. I am getting some stringyness. Not enough to bother me for this application. Not sure what the deal is. I don't really want to fiddle with it either.

In their new home, clearing just fine.

All dimensions in this model are parameters. This makes it trivial to change size. Next was to print it.

Checked status when I woke up this morning via the OctoPi. Looking good!

Fresh off the printer. I am getting some stringyness. Not enough to bother me for this application. Not sure what the deal is. I don't really want to fiddle with it either.

In their new home, clearing just fine.

- Joined

- Jan 20, 2021

- Messages

- 296

I can't picture it will be any less durable. Especially for my needs. Being able to make them the size I want/need is awesome.@slodat

Nice DIY solution.

I'm not knowledgeable about the material properties of printed PETG. Do you expect the printed boxes to be as durable as standard Schaller boxes?