Well..I spent a lot of years turning wrenches. And I had a Peugeot 505 that I thought was one of the sweetest driving cars I ever owned. I ended up selling it because Peugeot pulled out of the US. If I had internet access back then, I wouldn't have sold the car. But I was afraid of parts access. It was such a well driving and comfortable car. I would say it easily rivaled my 1991 MB 300E.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2021 POTD Thread Archive

- Thread starter Gaffer

- Start date

- Joined

- Jul 14, 2017

- Messages

- 2,448

Tim, i love hearing the 505 stories, many people around the world have had some good or bad experience with them. In the US, you had the best two series of peugeot X04 and X05, mid 2000 peugeot made some of the best looking cars but they stuck with X05 drivetrains and bulletproof suspensions just call them X06. New generation peugeots ones with big mouths X07, X08 series, are full of problems and a disgrace to the Peugeot name. That's one reason why i keep driving and restoring the old ones.Well..I spent a lot of years turning wrenches. And I had a Peugeot 505 that I thought was one of the sweetest driving cars I ever owned. I ended up selling it because Peugeot pulled out of the US. If I had internet access back then, I wouldn't have sold the car. But I was afraid of parts access. It was such a well driving and comfortable car. I would say it easily rivaled my 1991 MB 300E.

"Made" some shop space;

"That ho has got to go" was a joke started by me and a bud. We help each other build shop "stuff". Mostly heavy work,because of our ages. He has a table saw,bandsaw,and a cpl other pieces that needed to vacate his really nice garage. So we're building a nice add-on shop to his equipment shed.

In my case,it "was" an old gubment desk that was parked in a well fitted cubby in the machine shop. It's original purpose 20 years ago has LOOOONG been displaced by it just being another horizontal surface begging,and receiving a pile of junk on it's top.

That ho has got to go!

The desk is now in our equipment shed,as a purgatory of sorts. Gonna throw an old radial arm saw on it and cut some steel with it. Also,possibly turn it into a grinding station of some sort? But it's a mighty short step from there,to the dump.

But it AIN'T in my shop anymore,thank goodness! So,I made some space. Now,to use it wisely.... not,just parking something in it?

"That ho has got to go" was a joke started by me and a bud. We help each other build shop "stuff". Mostly heavy work,because of our ages. He has a table saw,bandsaw,and a cpl other pieces that needed to vacate his really nice garage. So we're building a nice add-on shop to his equipment shed.

In my case,it "was" an old gubment desk that was parked in a well fitted cubby in the machine shop. It's original purpose 20 years ago has LOOOONG been displaced by it just being another horizontal surface begging,and receiving a pile of junk on it's top.

That ho has got to go!

The desk is now in our equipment shed,as a purgatory of sorts. Gonna throw an old radial arm saw on it and cut some steel with it. Also,possibly turn it into a grinding station of some sort? But it's a mighty short step from there,to the dump.

But it AIN'T in my shop anymore,thank goodness! So,I made some space. Now,to use it wisely.... not,just parking something in it?

- Joined

- Mar 25, 2013

- Messages

- 4,617

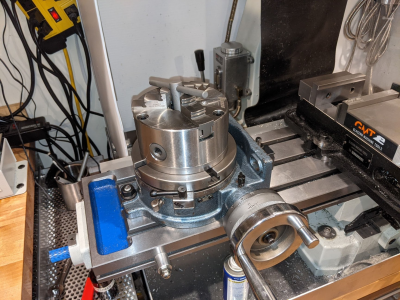

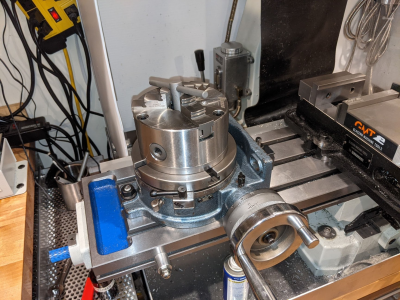

I got my 5" TMX chuck mounted on my Yuasa 6" rotary table.

I bought the back plate on Amazon. It was so far out of spec, it was like buying raw stock. I machined both faces of the plate so it was truly flat. I re- machined the MT2 stub so it was actually...MT2. There was a little slop in the 95mm mounting flange but that allowed me to tap it into .0005 concentricity on a dowel pin. I will call this a win.

Hey, if you have this rotary table, what is the backlash in deg?

Robert

I bought the back plate on Amazon. It was so far out of spec, it was like buying raw stock. I machined both faces of the plate so it was truly flat. I re- machined the MT2 stub so it was actually...MT2. There was a little slop in the 95mm mounting flange but that allowed me to tap it into .0005 concentricity on a dowel pin. I will call this a win.

Hey, if you have this rotary table, what is the backlash in deg?

Robert

- Joined

- Aug 22, 2012

- Messages

- 4,121

just my sand bound with sodium silicate (water glass) set with co2, it was hollow with a breather hole all the way through but it must have still been wet in the middle as it gassed terribly.

There is also a little shrinkage on one face of each block where I didnt bother setting up a feeder as they are oversize and will be squared off.

There is also a little shrinkage on one face of each block where I didnt bother setting up a feeder as they are oversize and will be squared off.

- Joined

- Jan 2, 2014

- Messages

- 8,853

Any details of that posted?Did a quick casting to test the new burner.

Thanks,

-brino

- Joined

- Oct 28, 2020

- Messages

- 528