- Joined

- Jun 21, 2020

- Messages

- 26

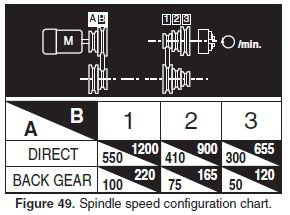

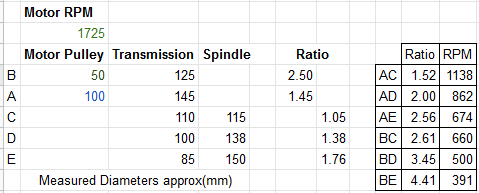

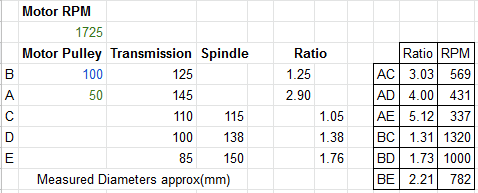

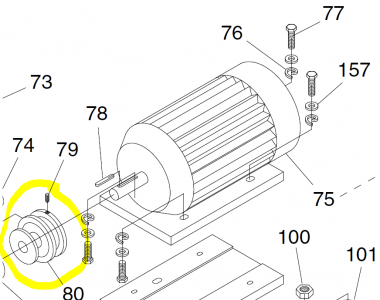

OK, I got out to storage today and made the measurements. These are for my motor and my G9249 which I purchased in 2000.

As you can see the layout is very different, my numbers are shown in red.

View attachment 332866

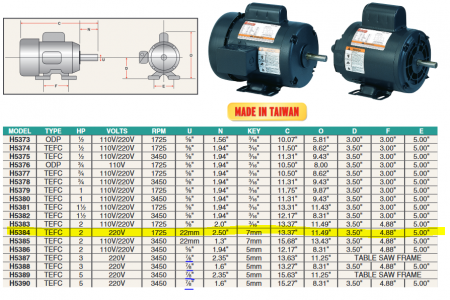

Here is an image of the plate on my motor

Thanks, super helpful. I think I'm going to hold off on more G9249 parts and see about maybe jet parts at replacements. The JET BD-1336T seems to be a pretty close make, but that's been tough to verify has replacements.

There's the BDB1340 which looks to be a modernized equivalent and that uses a BDB1340-MP pulley that may work. According to the info it has a 19mm ID which makes sense from what I'm seeing. I'm going to order one and hopefully this toolpartspro website doesn't take as long as the reviews indicate. Then when I get it figure out what motor fits best.