- Joined

- Dec 18, 2019

- Messages

- 6,448

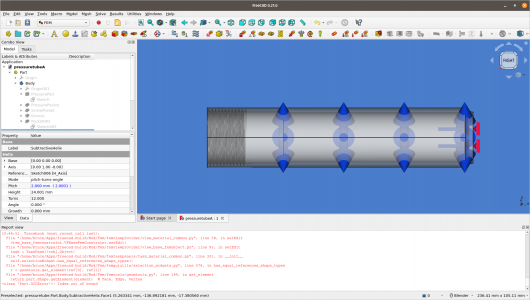

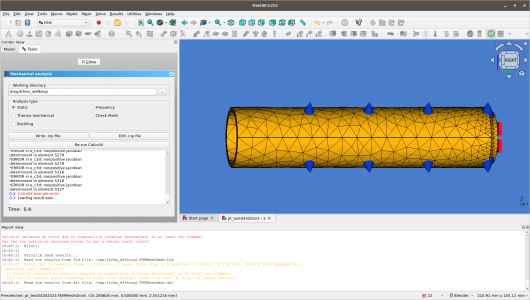

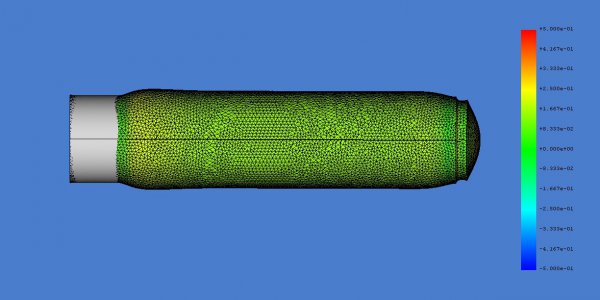

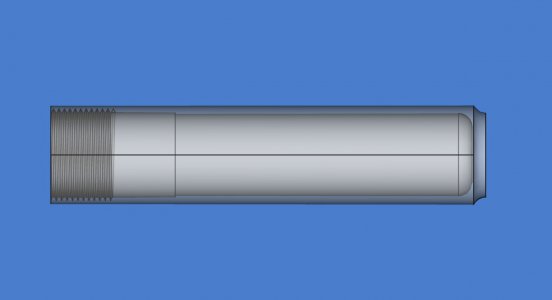

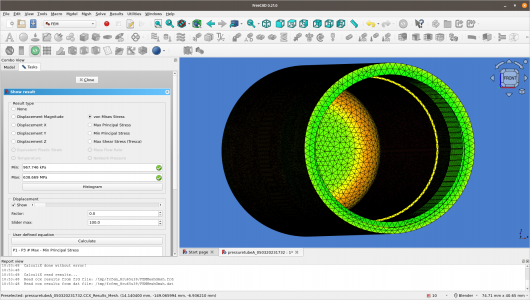

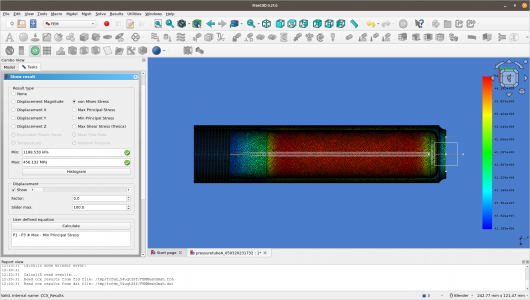

It seems the docs haven't quite caught up with the software. Trying to see what happens if one internally pressurizes an aluminum cylinder acting as a pressure vessel. It's a toy exercise for me, but the one example of FEM I found is using a different version of the tools. Having difficulties applying the constraints, and getting a mesh to work. I know the design is not best practice for a pressure vessel - I want to see where the stresses are.

There's an o-ring seal on the smooth inner ID, that prevents the threads from being pressurized. I've been told, and have seen other simulations that show sharp inside corners are very bad. I'd like to see those stresses show up in my FEA. Any tips or pointers would be appreciated.

There's an o-ring seal on the smooth inner ID, that prevents the threads from being pressurized. I've been told, and have seen other simulations that show sharp inside corners are very bad. I'd like to see those stresses show up in my FEA. Any tips or pointers would be appreciated.