29. I cleaned it and put it back on. I'm waiting to oil everything at once.

30. Thanks. I'll re-install them and get them adjusted.

I agree with Craig ("WCraig"); thanks doesn't begin to show my appreciation. On all the other forums for my other hobbies/obsessions, I get about 20 experts giving my questionable advice and one or two with the answer I'm looking for. Robert, you're the only one who responds on this forum (does no one else have anything to say?!

) and your advice is detailed and very helpful.

My hope and purpose for doing this thread is to help others. I don't normally toot my own horn ("Hey, look at me restore my lathe!"), but it occurred to me that this would help others doing the same thing. I read a lot of these myself and find them helpful. Thought I'd return the favor.

MOTOR

31. I cleaned up the motor. I found a bunch of bases for it.

Upper right and lower right don't fit anything. Anyone know what they might fit?

Lower left appears to be a correct one, but the motor would sit a bit lower and it's not quite wide enough for the existing motor. I'll keep this one.

Motor label:

Here's the writing:

660017

PT. NO. 84973

MODEL G-553

SKC49PR31CS

HP: 1/2 E25382

RPM: 1725/1140/850

V: 115

CY: 60

A: 82/75/72

CODE: J AKR52

PC: 8810M

RISE: 70 degrees C. CONT.

DATE: 404

It appears to be a 3-speed motor (there are several stickers on it that have that written on it). When I got it, the homemade switch plate had "forward", "reverse" and "stop" labelled.

I plan on getting a linkbelt so I can change it easily.

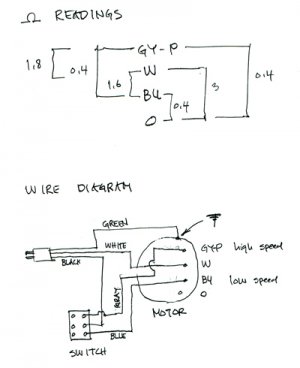

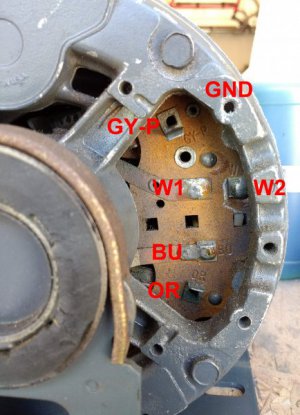

There are 4 tabs to connect wires to:

GY-P

W

BU

OR

I need to get a new cord and plug.

What goes where? The ground wire screws into the motor housing, so that's one wire solved. When I got the lathe, the motor ran, but I needed to unplug it to make the whole assembly lighter so we could load and unload it. I didn't note what wires went where at the time.

This appears to be a replacement motor, so I'm not sure a wiring diagram would help. I just need to know what the letters above mean (colors?) and then I think I can connect it to a switch.

I have the old wires and might be able to solve the puzzle.

Also, if it's a 3-speed motor I'd like to wire it as such; it was wired for forward, reverse and stop when I got it, so using the existing wires as a guide might not help.

How much damage can I do hooking it up wrong?