-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ARC-170's Craftsman 101.07403 lathe restoration thread

- Thread starter ARC-170

- Start date

- Joined

- Oct 17, 2018

- Messages

- 922

I need to catch up with this thread, but what type of pulley are you using? I'm assuming its one you can change without disassembling the headstock?

Do you mean pulley belt? I'm using a link belt I got at Harbor Freight. I thought I'd try it out. I wanted one I could change with taking the spindle off. It was a real pain!

- Joined

- Oct 17, 2018

- Messages

- 922

Interesting, I didn't realize they sold them at HF....I was just in there yesterday picking up a 1/2 HP motor for my Craftsman 12" lathe.

It's called a "vibration free link belt". They are about $35 less the 20% off with coupon.

https://www.harborfreight.com/vibration-free-link-belt-43771.html

The red ones (that HF copied) are $14 a foot at Rocklers. I got about 5 ft at HF (about $6/ft). I needed two belts for my lathe, though. One didn't have quite enough.

- Joined

- Oct 17, 2018

- Messages

- 922

5' should be plenty long for the main belt, though.

There are two belts and one 5' long one wasn't enough. I needed about 65". I have 55" left over. I was mildly annoyed, but I'm over it now.

- Joined

- Dec 25, 2011

- Messages

- 10,511

F. I am somewhat handicapped by the fact that I don't know what the back side of the bed and L6-150L headstock end leg look like. No parts drawing shows anything but a front view and AFAIK no owner has ever photographed the back side of the lathe with motor moved out of the way. But it appears to me that the L6-20 Countershaft Bracket is mounted much too far to the left (as looked at from the front of the lathe). Maybe as much as 3/4" to 1" too far. And that the L3-107 Spindle is too far to the left and that the 10-80 Pulley is too far to the right on the spindle. The spindle should stick out through the right bushing a little bit. Do not assume that as found it was correctly assembled.

- Joined

- Oct 17, 2018

- Messages

- 922

35. SPINDLE ALIGNMENT (CON'T)

I took another look at the assembly. All the brackets that hold the spindles and pulley are lined up correctly. Here are some pictures of the back from various angles:

I was able to pull spindle A off and get the pulley off as well. This is what is misaligned. Pulling it off and re-doing it is the best way to get this fixed. I wasn't able to move it at all before, but I tried a different method (taking it off the lathe and hitting it with a metal rod) and got it off. The bigger pulley (the one hooked to the motor belt) was stuck because the metal was gouged (I used a puller to get it off). Pulley A was just stuck. It's really scored on the inside. I have a better one from the donor lathe I will use. I might have to use a different axle as well. They are currently soaking in Simple Green.

36. BELT ALIGNMENT

I did a little research and it appears the belts cannot be misaligned much at all. The loosest tolerance I found was 1/10" deflection per foot of drive center distance. Most of them were around 0.001-0.005"/inch of pulley diameter (so a 5" diameter pulley can be 0.005-0.025" off). So it appears, to answer my own question, that these need to be aligned as close as possible.

F. I am somewhat handicapped by the fact that I don't know what the back side of the bed and L6-150L headstock end leg look like. No parts drawing shows anything but a front view and AFAIK no owner has ever photographed the back side of the lathe with motor moved out of the way. But it appears to me that the L6-20 Countershaft Bracket is mounted much too far to the left (as looked at from the front of the lathe). Maybe as much as 3/4" to 1" too far. And that the L3-107 Spindle is too far to the left and that the 10-80 Pulley is too far to the right on the spindle. The spindle should stick out through the right bushing a little bit. Do not assume that as found it was correctly assembled.

I took another look at the assembly. All the brackets that hold the spindles and pulley are lined up correctly. Here are some pictures of the back from various angles:

I was able to pull spindle A off and get the pulley off as well. This is what is misaligned. Pulling it off and re-doing it is the best way to get this fixed. I wasn't able to move it at all before, but I tried a different method (taking it off the lathe and hitting it with a metal rod) and got it off. The bigger pulley (the one hooked to the motor belt) was stuck because the metal was gouged (I used a puller to get it off). Pulley A was just stuck. It's really scored on the inside. I have a better one from the donor lathe I will use. I might have to use a different axle as well. They are currently soaking in Simple Green.

36. BELT ALIGNMENT

I did a little research and it appears the belts cannot be misaligned much at all. The loosest tolerance I found was 1/10" deflection per foot of drive center distance. Most of them were around 0.001-0.005"/inch of pulley diameter (so a 5" diameter pulley can be 0.005-0.025" off). So it appears, to answer my own question, that these need to be aligned as close as possible.

- Joined

- Dec 25, 2011

- Messages

- 10,511

OK. Now we know what the mounting looks like. The first version on the 618 was similar. It was only made for about a year before they changed it to look something like the horizontal countershaft on the 10". I've no idea why theyh changed it nor why they made the 10" look like it does. They would have saved a lot of people a lot of trouble had they made all three look the same.

Thanks for researching the belt alignment question. I knew that it had to be pretty close but didn't know the numbers.

Thanks for researching the belt alignment question. I knew that it had to be pretty close but didn't know the numbers.

- Joined

- Oct 17, 2018

- Messages

- 922

35-36. SPINDLE & BELT ALIGNMENT (CON'T)

Spindle and belt alignment are complete. I took everything apart and painted the pieces. The gears and belts are all aligned. I cleaned up the shafts, got a new Woodruff key for the rear motor spindle and everything went together easy. I also put a small piece of lead in the set screw holes so the shaft doesn't get gouged.

37. LUBE QUESTION

On top for the bracket that holds the motor and spindles (#L3-20) there are some oil cups. There are no holes in under them, though. How do these work? Are the bushings some sort of material that absorbs the oil? How long does it take and how do I tell if these are lubed?

38. GEAR GUARD (#10D-247)

The donor lathe I bought had this part on it. It will fit on my lathe, but it's not listed in my parts list even though everything else is listed. However, once I got the pulleys and gears aligned, there is no room for it to fit. Just wondering what it is and why it's not listed. It seems redundant; the bigger pulley guard goes over this area.

39. SIDE GUARD

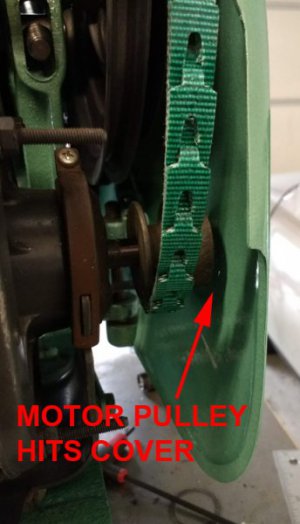

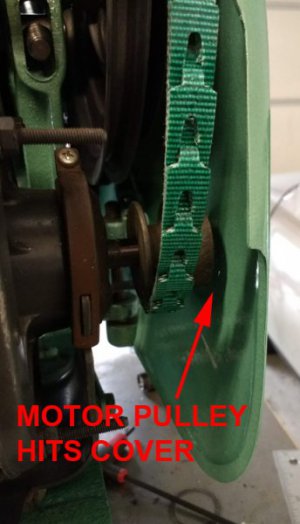

I'm having some issues with getting the big side door to close. It hits the motor pulley shaft.

I can get it to close if I lift up on it, but as soon as I release it, it goes back to it's original position. All the pieces it's connected to are tight. I thought I might need to adjust them a little, but there doesn't seem to be much play. I thought I might add wedges under the mounting bracket as shown to lift it up. Thoughts about this particular solution?

Here is a picture showing where the pulley hits the cover. In this photo, there is just barely enough clearance. The solution would appear to be moving the whole motor.

When I try to move the whole motor, there is no more hole to place a bolt. The slot in the base isn't long enough:

And, if I move it too much I may not have enough shaft to align the pulley on the motor and the counter shaft pulley. I can switch the belt to the bigger counter shaft pulley, I think, but this will just mean I can't run the other speed.

Should I drill a hole in the motor base on the lathe or on the gray motor base attached to the motor? I have a few other motor bases that came with the lathe, but none of them fit the motor.

I'll play with it some more, but I'd like to hear some other suggestions. Maybe I'm missing something.

Spindle and belt alignment are complete. I took everything apart and painted the pieces. The gears and belts are all aligned. I cleaned up the shafts, got a new Woodruff key for the rear motor spindle and everything went together easy. I also put a small piece of lead in the set screw holes so the shaft doesn't get gouged.

37. LUBE QUESTION

On top for the bracket that holds the motor and spindles (#L3-20) there are some oil cups. There are no holes in under them, though. How do these work? Are the bushings some sort of material that absorbs the oil? How long does it take and how do I tell if these are lubed?

38. GEAR GUARD (#10D-247)

The donor lathe I bought had this part on it. It will fit on my lathe, but it's not listed in my parts list even though everything else is listed. However, once I got the pulleys and gears aligned, there is no room for it to fit. Just wondering what it is and why it's not listed. It seems redundant; the bigger pulley guard goes over this area.

39. SIDE GUARD

I'm having some issues with getting the big side door to close. It hits the motor pulley shaft.

I can get it to close if I lift up on it, but as soon as I release it, it goes back to it's original position. All the pieces it's connected to are tight. I thought I might need to adjust them a little, but there doesn't seem to be much play. I thought I might add wedges under the mounting bracket as shown to lift it up. Thoughts about this particular solution?

Here is a picture showing where the pulley hits the cover. In this photo, there is just barely enough clearance. The solution would appear to be moving the whole motor.

When I try to move the whole motor, there is no more hole to place a bolt. The slot in the base isn't long enough:

And, if I move it too much I may not have enough shaft to align the pulley on the motor and the counter shaft pulley. I can switch the belt to the bigger counter shaft pulley, I think, but this will just mean I can't run the other speed.

Should I drill a hole in the motor base on the lathe or on the gray motor base attached to the motor? I have a few other motor bases that came with the lathe, but none of them fit the motor.

I'll play with it some more, but I'd like to hear some other suggestions. Maybe I'm missing something.