- Joined

- Dec 22, 2011

- Messages

- 310

VSA, is it easy to switch between pulleys ? That is change speeds.. On mine the belt is very close to the mount, at the moment the link belt lets me disassemble the belt to move between pulley sheeve selections.

Yeah, it's pretty easy to switch the belt with the tension released. I think the link belts are bulkier, so that might be part of the problem if you don't have room to slip the belt over the pulley steps.

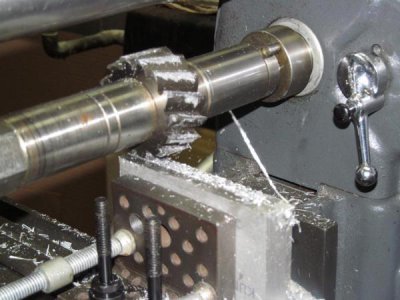

I got the motor wired up and installed tonight. It's running, but there seems to be an issue with the back gear. Even with the pin in the bull gear pulled out, the bull gear and spindle pulley still seem to spin together. They must be binding somewhere. I will have to see if I can get it sorted out. The motor bearings are also a little noisy and I suspect they need replacing.