Well, the stand(s) are ready.

I appreciate the good input and challenges.

Was helpful.

I have a truck with a trailer parked out front, and tomorrow is D Day.

Knuckles are cut.

Back is sore.

Beer is cold.

To end my night, I had a tiny metal splinter find its way in to my foot.

I'm sure I'm not the first...

The damn thing was almost invisible to the eye - but not to the mind. Ouch.

Unable to see it like a normal splinter - I pulled out my $30 electronic microscope.

Do you guys have one of these?

I use it for everything - they are - incredible.

When I start milling - I will use it to show some detail - and you guys can tell me what I am doing wrong.

Smooth surfaces look like the moon surface.

Below a few pictures on the eve of pick up for your viewing pleasure.

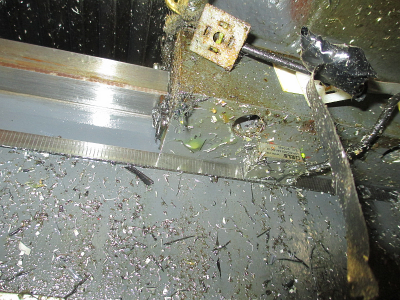

Current face milling technique:

View attachment 367413

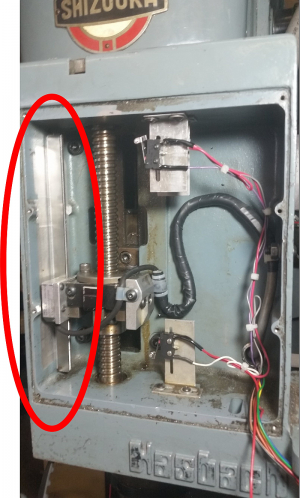

Face mill tools. I have a bunch already.

View attachment 367414

And of course - the rolling stand(s). Just about complete.

Plan is to cut some angles on the leveling feet extensions/ prime/ install.

View attachment 367416