-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

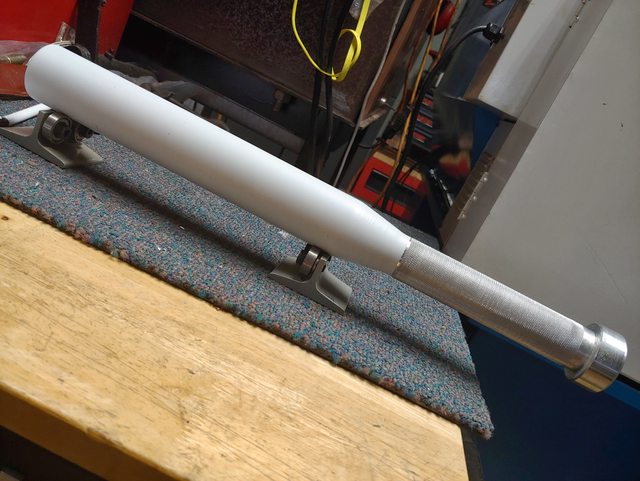

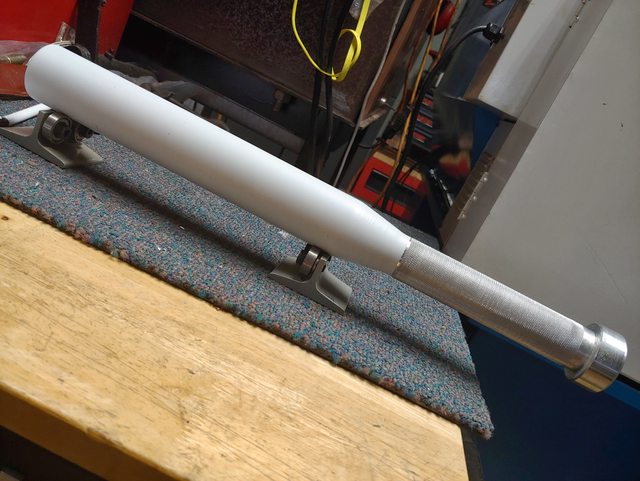

Billet aluminum bat

- Thread starter Aukai

- Start date

- Joined

- Oct 4, 2016

- Messages

- 7,021

I thought I had a plan for the taper not knowing how to do it, and it didn't work I was thinking that I could measure the travel of the cross slide, set the angle to give me the 1/2" DOC over 3"s, and as the cut got deeper just engage the carriage to take the cut down the handle, then return. Reset to continue the taper, cut repeat down the handle. I got to the handle dimension before the full taper was cut, short 1" of taper. I have zero math skills, so this will be trial, and error

I was thinking that I could measure the travel of the cross slide, set the angle to give me the 1/2" DOC over 3"s, and as the cut got deeper just engage the carriage to take the cut down the handle, then return. Reset to continue the taper, cut repeat down the handle. I got to the handle dimension before the full taper was cut, short 1" of taper. I have zero math skills, so this will be trial, and error

I measured 1/2" away from the bat at the start of the taper, and set the angle to just touch the bat at full cross slide travel. I then moved the tool to touch at the start, hand fed the cross slide, and did as described above, I messed it up some how...

I was thinking that I could measure the travel of the cross slide, set the angle to give me the 1/2" DOC over 3"s, and as the cut got deeper just engage the carriage to take the cut down the handle, then return. Reset to continue the taper, cut repeat down the handle. I got to the handle dimension before the full taper was cut, short 1" of taper. I have zero math skills, so this will be trial, and error

I was thinking that I could measure the travel of the cross slide, set the angle to give me the 1/2" DOC over 3"s, and as the cut got deeper just engage the carriage to take the cut down the handle, then return. Reset to continue the taper, cut repeat down the handle. I got to the handle dimension before the full taper was cut, short 1" of taper. I have zero math skills, so this will be trial, and error

I measured 1/2" away from the bat at the start of the taper, and set the angle to just touch the bat at full cross slide travel. I then moved the tool to touch at the start, hand fed the cross slide, and did as described above, I messed it up some how...

Last edited:

- Joined

- Apr 29, 2019

- Messages

- 2,060

Unless you have a taper attachment or you are setting up with the tail stock offset, you can not use power feed to make a taper.

You will have to set the cross slide angle and then hand feed the cross slide for the whole length of the taper cut. If your cross slide does not have that much travel then you will have to do it in steps and hand finish out the line between sections (unless you are REALLY good at picking up the cut).

A 9.5° angle at 0.500 deep will give you a taper that is 2.988 long, only 0.012 off, prolly close enough for an ice bat.

If you really need 0.500 deep and 3.000 long then the angle will be 9.4623222°

You will have to set the cross slide angle and then hand feed the cross slide for the whole length of the taper cut. If your cross slide does not have that much travel then you will have to do it in steps and hand finish out the line between sections (unless you are REALLY good at picking up the cut).

A 9.5° angle at 0.500 deep will give you a taper that is 2.988 long, only 0.012 off, prolly close enough for an ice bat.

If you really need 0.500 deep and 3.000 long then the angle will be 9.4623222°

- Joined

- Oct 4, 2016

- Messages

- 7,021

Dang, I knew there would be a math solution, thank you. I did this last one at 10* hand feeding, and running the power feed to clear the DOC, then returned to the shoulder. Somewhere in this procedure it/I some how shortened the taper when I continued the hand feed/power feed combination. I'm also using an aluminum primer now too, the bat on the boat turned gray right away with the salt.

- Joined

- Sep 28, 2013

- Messages

- 4,307

something else to look into - a home anodising set up! Then you can add $20 to the bat for the colour of their choice

- Joined

- Sep 28, 2013

- Messages

- 4,307

pretty durable in my experience. Some dyes will fade in sunlight (red especially) and the anodising will wear at high spots with use, but other than that it'll last years. I made the light below about a year and a half ago (I think) and it's been exposed to about 9000 miles of baking sun, miserable rain and everything in between. Still looks just the same

takes a bit of investment - some 5 gallon buckets, titanium wire, 10A30V adjustable power supply and dyes (about $10 ea from Caswell), but once you have it set up there's not really any extra cost other than different colours.

takes a bit of investment - some 5 gallon buckets, titanium wire, 10A30V adjustable power supply and dyes (about $10 ea from Caswell), but once you have it set up there's not really any extra cost other than different colours.

- Joined

- Jan 31, 2016

- Messages

- 11,449

Put the cash into a coffee can and use it for buying new tools or cold beverages.

Now we're talkin !

Mike , that bat would take less then 5 minutes on a CNC lathe . Should I be on the lookout for one to ship over there ?