- Joined

- Jun 12, 2014

- Messages

- 4,817

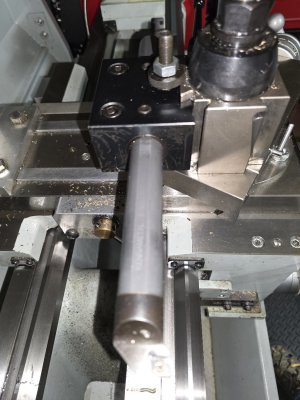

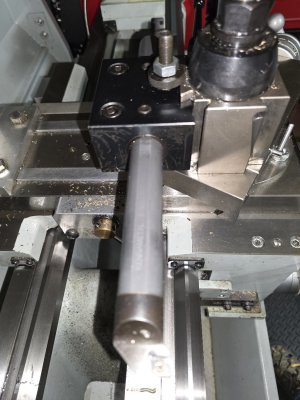

If the split ring does not clamp fully then probably wrong size boring bar and/or spot ring does not have a wide enough split. I did add two screws to the top of my boring bar holder that go through the split ring and push directly on the boring bar flat. This was so it always maintains the same rotational position when moving it in/out. On smaller boring bars I use #2 tool post holders that have a groove on the bottom for boring bars.