- Joined

- Mar 26, 2018

- Messages

- 8,407

Oh I’m cutting baby!!The bar isn't the issue . The stick out is . Think of boring on the lathe . You have a 12" boring bar , you're going to get chatter . You have a 2" bar , you're not . Cut that shank if that's the only holder it will fit .

Dave, could you show me your boring set up?

If it’s too dang cold out there I understand.

How you feeling.

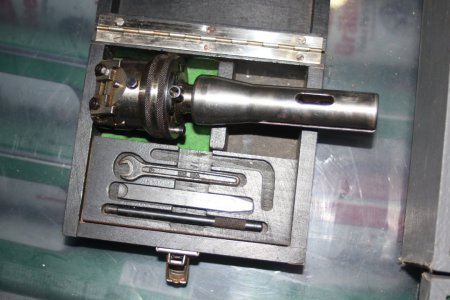

I sold every boring head I've ever owned Jeff . I have my Narex and my Wohlhaupter boring/facing heads left . Just thinning the herd out over the years .

I sold every boring head I've ever owned Jeff . I have my Narex and my Wohlhaupter boring/facing heads left . Just thinning the herd out over the years .