The leather is still pliable. There is a lot of crud build up around the outside sealing surface. Do you think i could use a deburring wheel to clean it? Or do i not worry about it? Thank you again for your input.

This is a good question. My gut instinct would be to avoid anything that might leave abrasive particles embedded in the leather. I think I would just try a good scrub with a wire brush (I'm thinking hand held "toothbrush" style wire brush). Anything that doesn't remove is probably best left where it is.

A bit disturbed at being considered the resident expert on leather seals, I did a bit of googling. Most of my attempts mostly produced information on leather sealants, but I hit some pay-dirt with "vintage leather hydraulic seal maintenance".

This produced some interesting results...including a worrying Pakistani Truck video. I think their approach to replacing the leather hydraulic seal is eminently sensible. It's the fact the work is being done under the probably inadequately suspended dump bed that looks questionable to me.

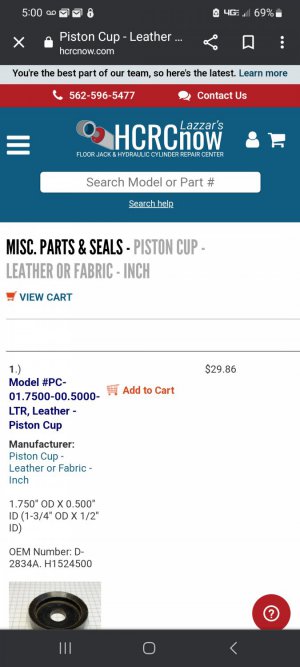

An HCRCnow.com website link does mention that hydraulic seals were originally made of leather and rope, but offers no more info on the subject.

@Provincial's assertion that an O-ring may not be up to the task is supported by a description in

McMaster's list of hydraulic cylinder seals, where it states that their high-pressure leather u-cup seals are rated for 10,000 psi and that this is over 80 times what the similar BUNA-N rubber seals are rated for. Mind Blowing!

McMaster does have cup seals that look similar to yours but they are also BUNA-N rubber and are only rated for 1,000 psi, which I'm fairly certain is inadequate for your 12 ton jack.

In any event some of those links might be of interest.....

-Pete