Sounds like a plan. The lovely thing about fabrication is if you stuff it up it's little work to rectify. Not like bozo-ing a casting where it's half a day of agony over how best to put it right. Grind it off, re-weld it! I reckon I'll freestyle my stand and motor drive to suit what I have to hand or can find easily. I'm way past falling into the trap of making something to drawing, then to find the thing it's supposed to mount isn't easily available over here. As long as the chain lines up and you get roughly the right ratios between the motor and flywheel it's all good.

Yep, got the CAD covered

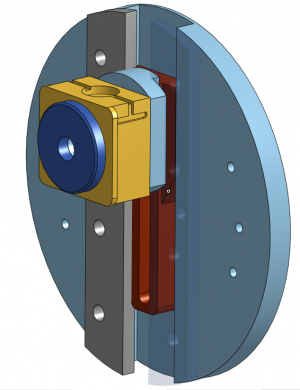

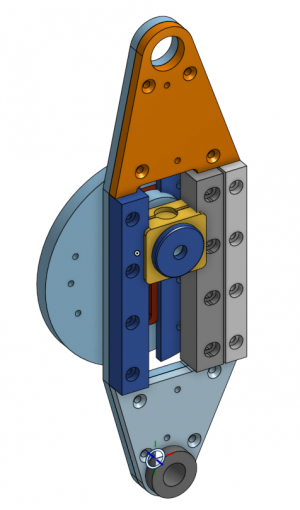

I'll produce some decent drawings for us to work off or it'll be painful. I 3D model then make drawings and a list of operations even for the little projects I do for myself. I've found it actually saves time and prevents a load of mistakes. It's s good sanity check that everything fits together too, I've got the flywheel and crank arm modeled up already:

View attachment 324570

Blame Abom79

hehe. There will be a build thread, for sure! I'll probably film and YouTube my build as it's something interesting and unique.