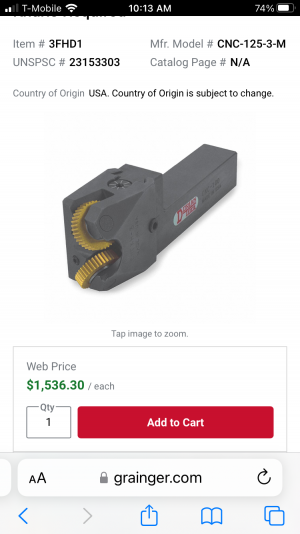

Hi wonder if anyone can help me? Today at a pawn broker I saw a cut knurl tool. It had not price so I asked the shop keep who said he was not sure as it was on his "old system" he eventually just said I could take it for the equivalent of about $20. I think I got a great score here but not really sure. Also I am totally unsure n how it actually gets used.

Can some help identify this tool? It has "Zeus 210" engraved on it so it looks like it is from Germany. Ideally looking for information on how exactly it is used? ie in what orientation I mount it on the lathe and how it is setup for different bar diameters?

Can some help identify this tool? It has "Zeus 210" engraved on it so it looks like it is from Germany. Ideally looking for information on how exactly it is used? ie in what orientation I mount it on the lathe and how it is setup for different bar diameters?